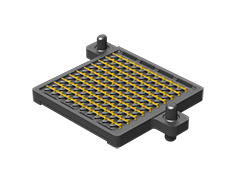

SUPERNOVA™ Low Profile Compression Interposers

High-speed, low profile one-piece interposers with a 1.27 mm body height and dual compression contacts.

GMI

1.00 mm SUPERNOVA™ Low Profile Compression Interposer

Features

- Dual compression contacts

- Up to 300 I/Os

- Low profile - 1.27 mm standard height

- Analog Over Array™ capable

CONTACT SALES

First Name

Last Name

Company

Industry

Estimate Annual Usage

Family

Message

Don't want to fill out a form?

Chat with a product expert directly.

More Compression Interposers

Your Privacy Choices

Your Privacy Choices