Custom Connectors and Cables with Samtec

Custom Connectors and Cables with Samtec

We've got you covered

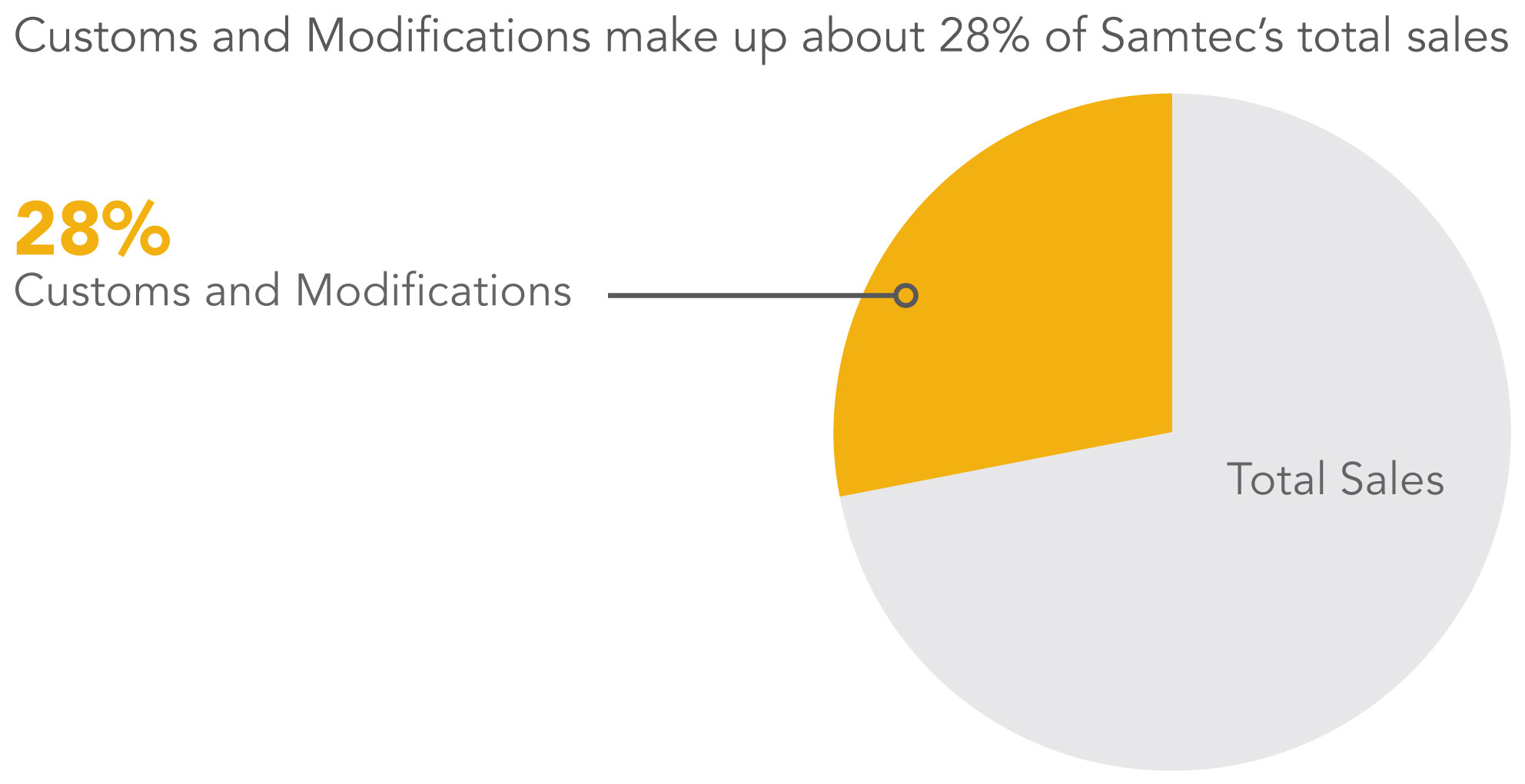

Most of our custom connectors and modified interconnects come with low or no NRE charges, quick-turn samples, short lead times, and low or no MOQ’s. This is why custom and modified products account for more than 20% of our business, and why we’ve consistently been ranked #1 in the industry for willingness to modify a product.

What will we customize?

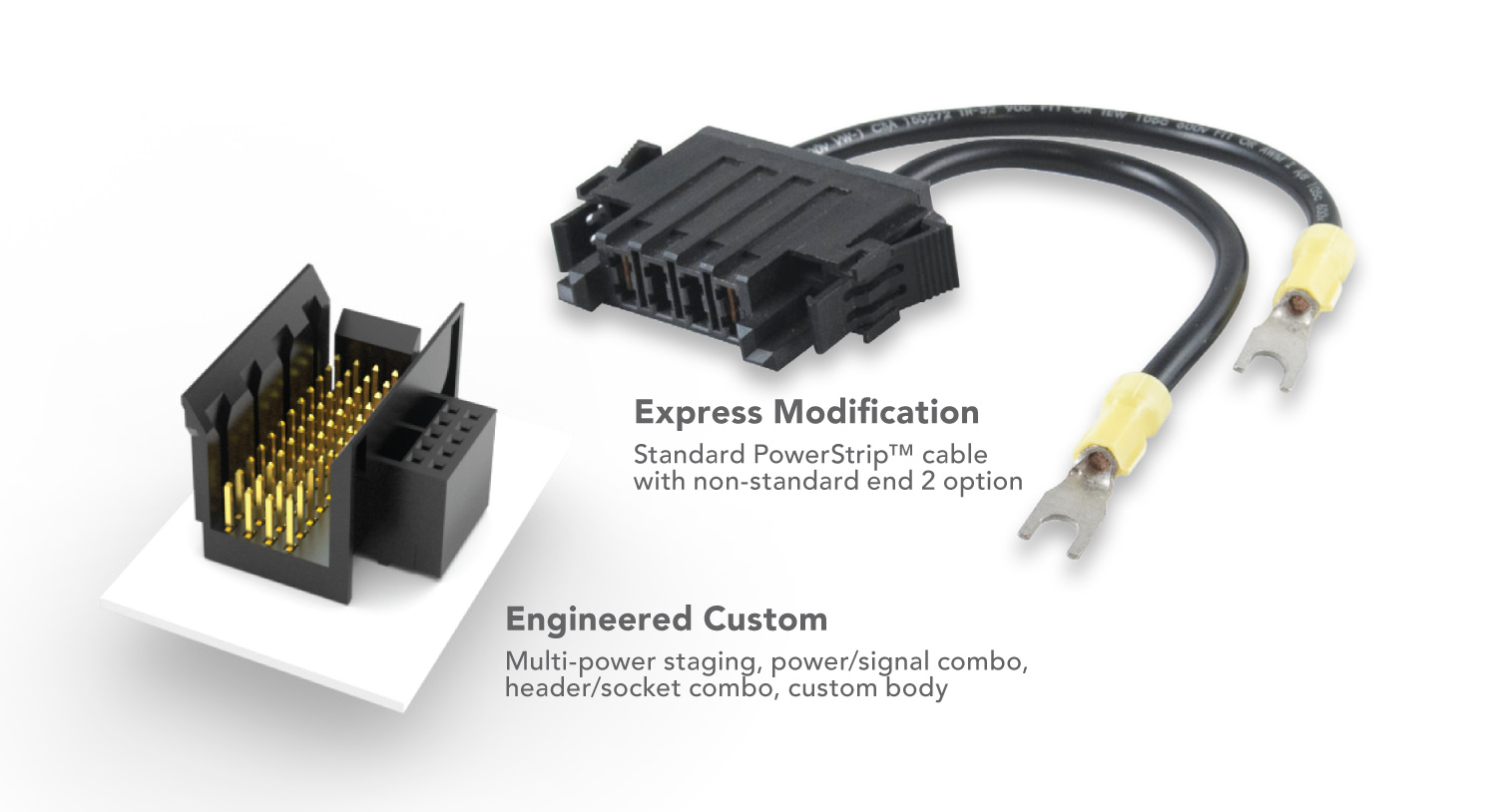

With dedicated Application Specific Product engineers and technicians, we are open to custom connectors and cables spanning every product category we offer, which includes both simple modifications as well as completely new and custom designs.

Completely new designs are possible, and our capabilities span the entire signal transmission line from the bare die to the panel and all points in between. Common simple modifications to board-to-board and cable products include:

- Plating

- Polarization

- Packaging

- Sheared posts

- Sheared tails

- Tail and post angles

- Post height modifications

- Labeling

- Ink printing

- Shielding modifications

What are the next steps to get started?

Call 1-812-944-6733, email us, or complete the form below to begin the easy process of getting exactly the product you need. Within 24 hours, someone will respond to clarify application and modification details, estimated annual usage, your targeted price per piece, and preferred delivery dates. You’ll know within 24 hours whether or not we can assist, and if so, we’ll provide an approximate price to help you determine if you would like to proceed. If the next steps are pursued, within a week you’ll receive a model and PDF print along with a formal quote to approve. Upon acceptance, you’ll soon have your custom or modified solution in-hand!

First Name*

Last Name*

Email*

Phone*

Company*

Please Describe Your Custom Modification Needs*

* These are required fields