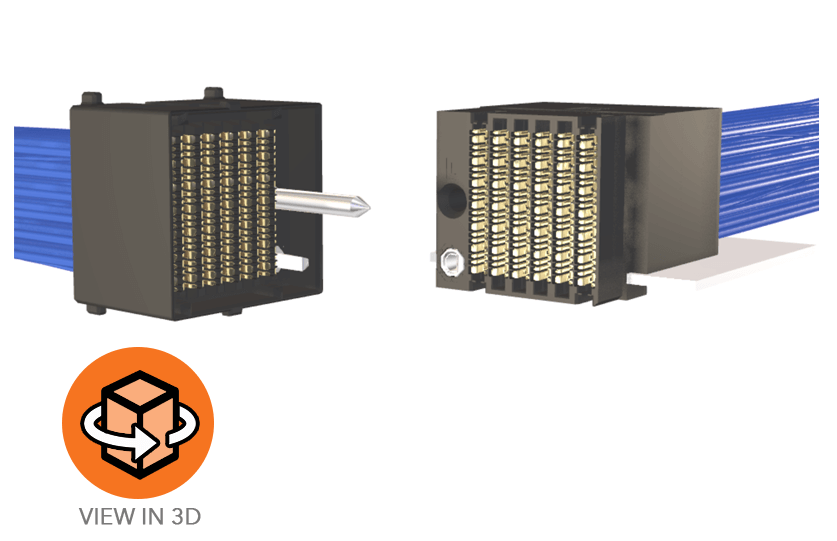

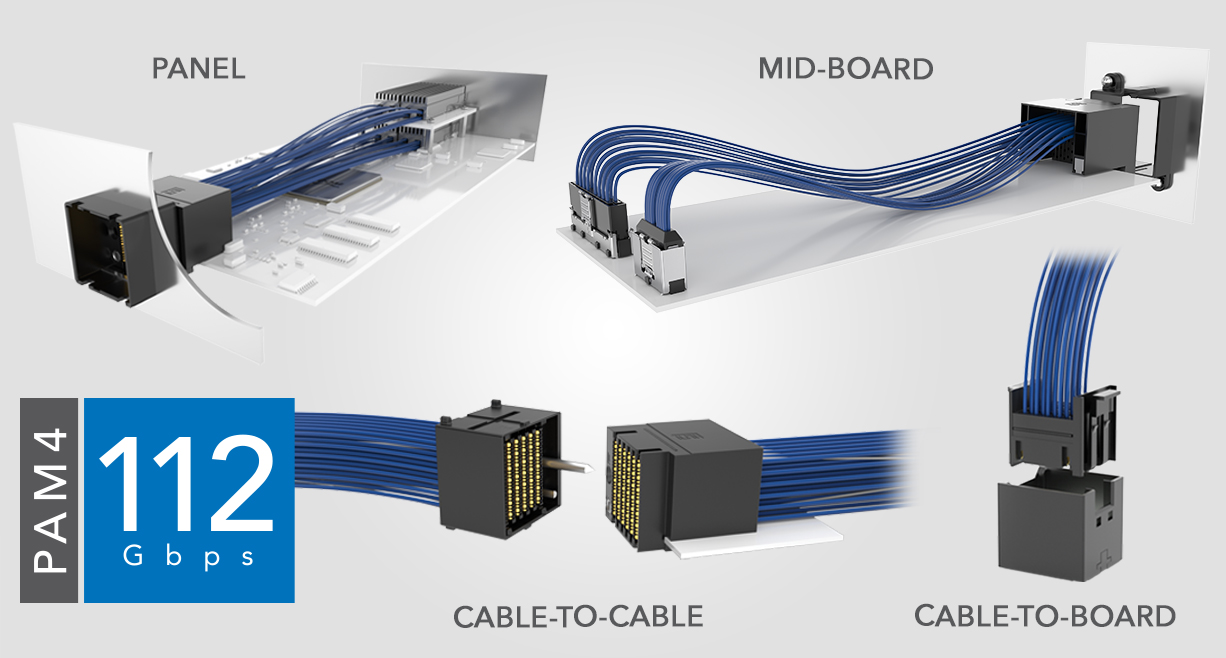

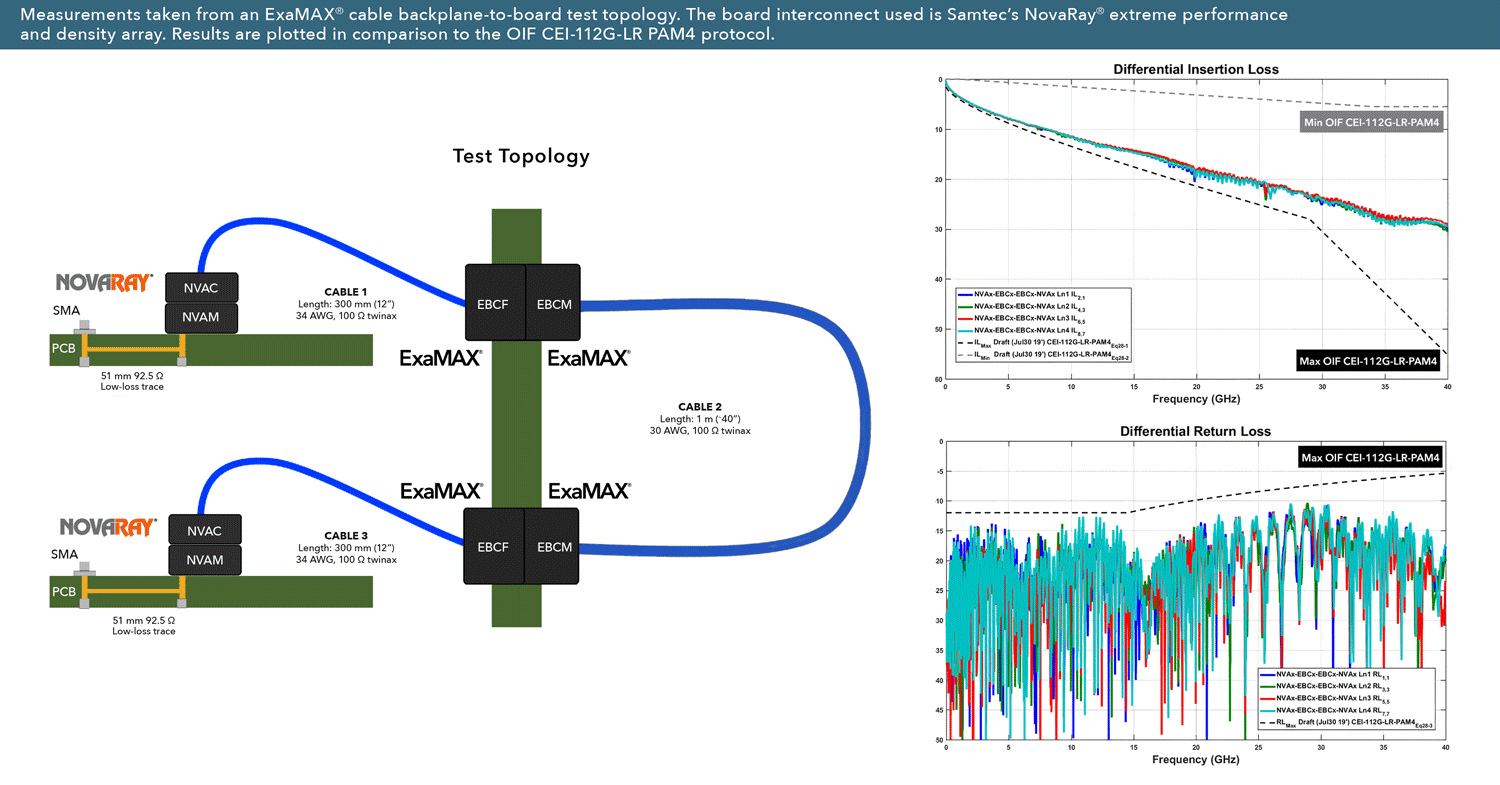

112 Gbps PAM4 cable assemblies: ExaMAX® backplane cable systems improve signal integrity and routability using Samtec Flyover® technology, which routes the signal above a lossy PCB using co-extruded, ultra-low skew twinax for improved bandwidth and reach. Direct solder attach to contacts optimizes the signal path, further enhancing performance. Supports 112 Gbps PAM4 applications and is PCIe® 6.0/CXL® 3.1 capable.

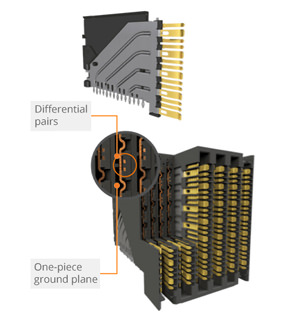

64 Gbps PAM4 interconnects: The ExaMAX® contact system achieves two reliable points of contact at all times and minimizes residual stub for improved signal integrity performance, while providing low mating force and excellent contact normal force. Signal wafers incorporate a one-piece, embossed ground structure which improves crosstalk. Supports 64 Gbps PAM4 (32 Gbps NRZ) applications and is PICe® 6.0/CXL® 3.1 capable.

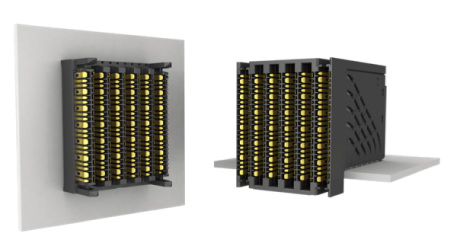

ExaMAX® Product Explorer