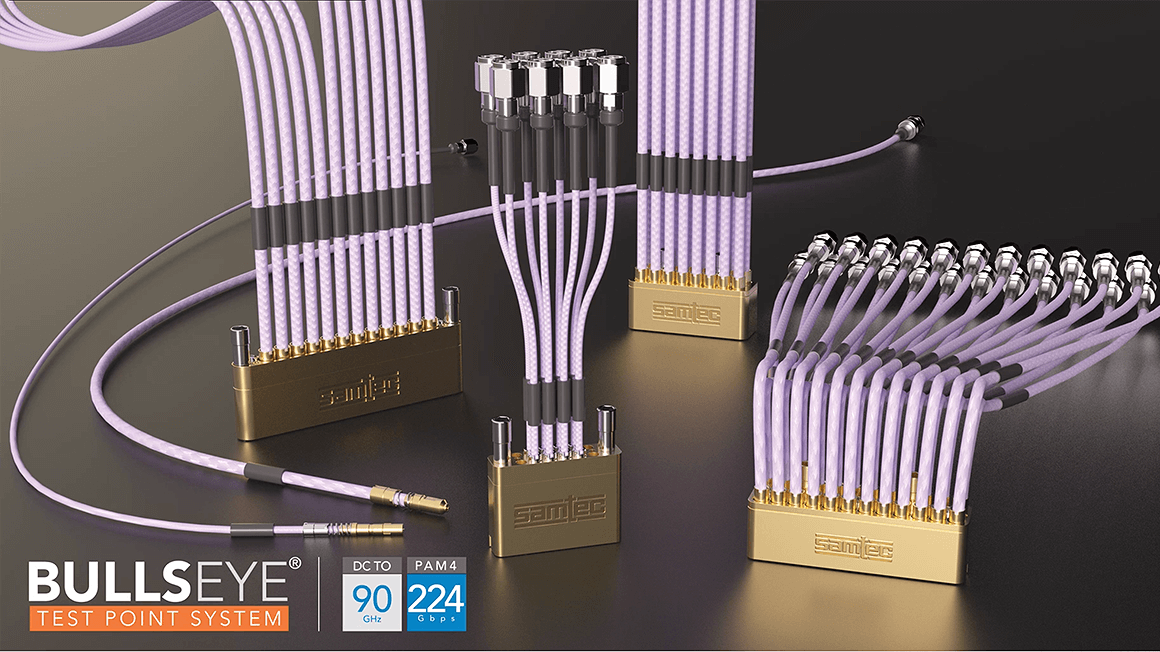

Bulls Eye® high-performance test assembly features a high-density space saving design that enables smaller evaluation boards and shorter trace lengths in test and measurement applications.

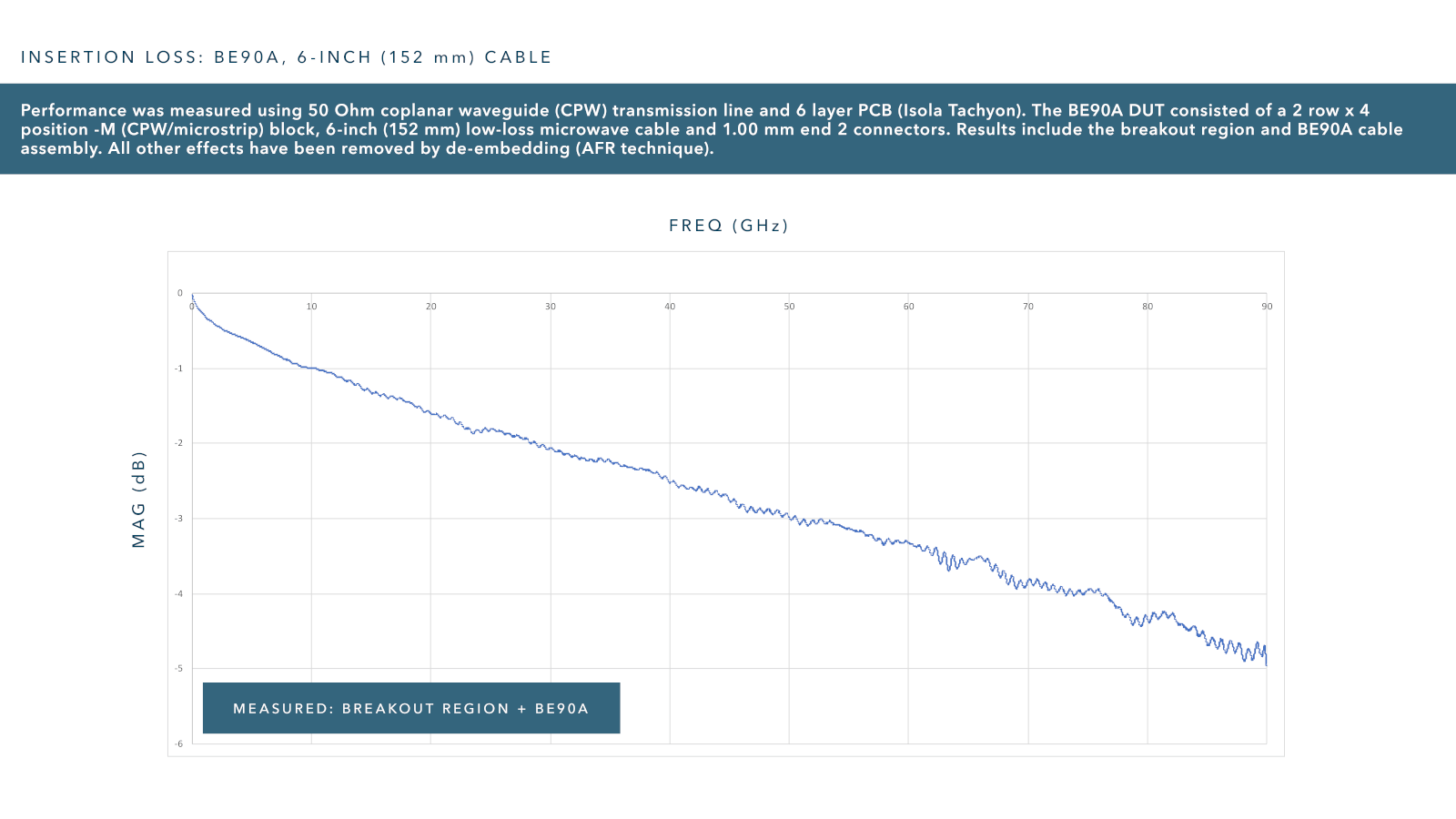

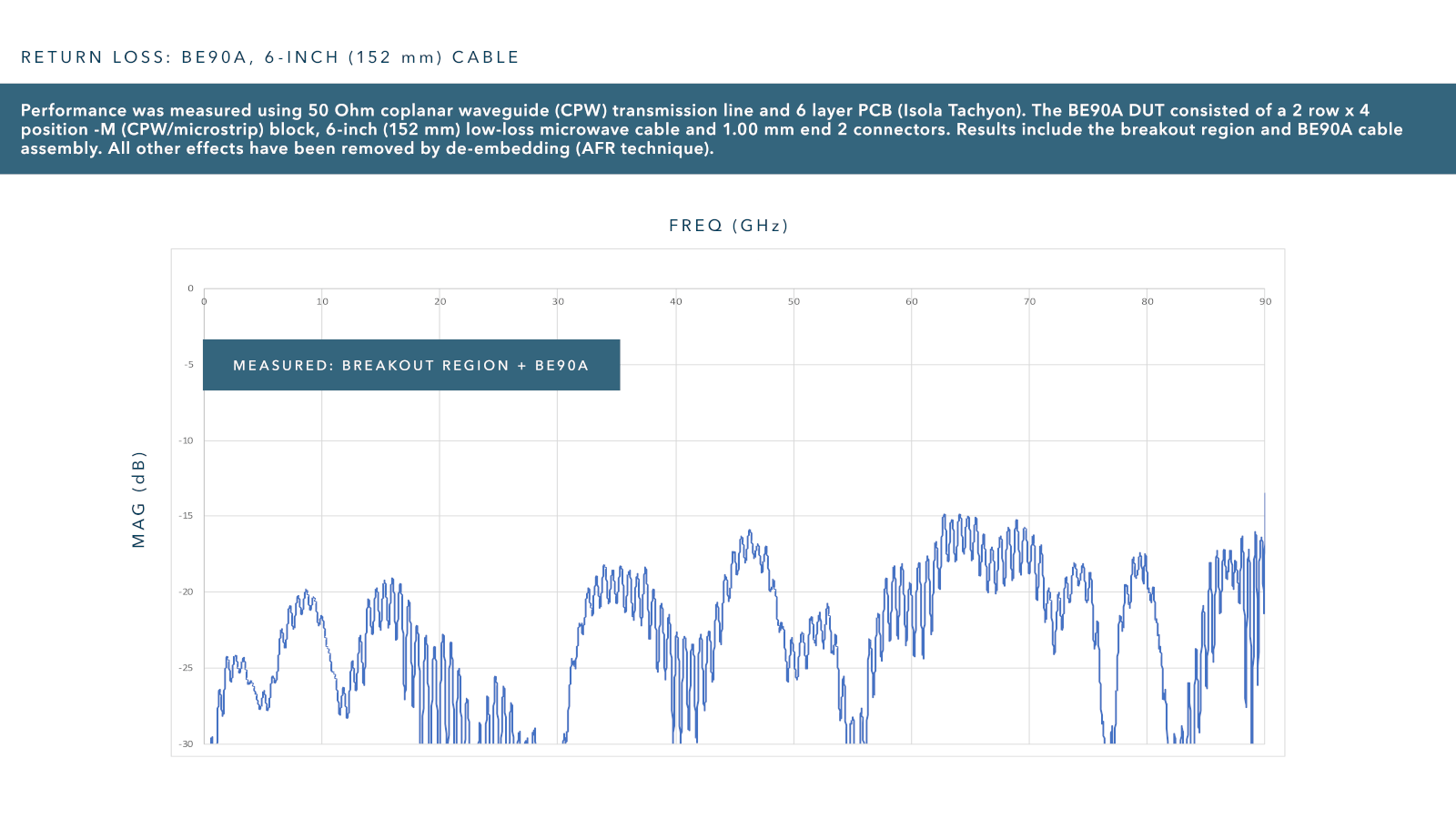

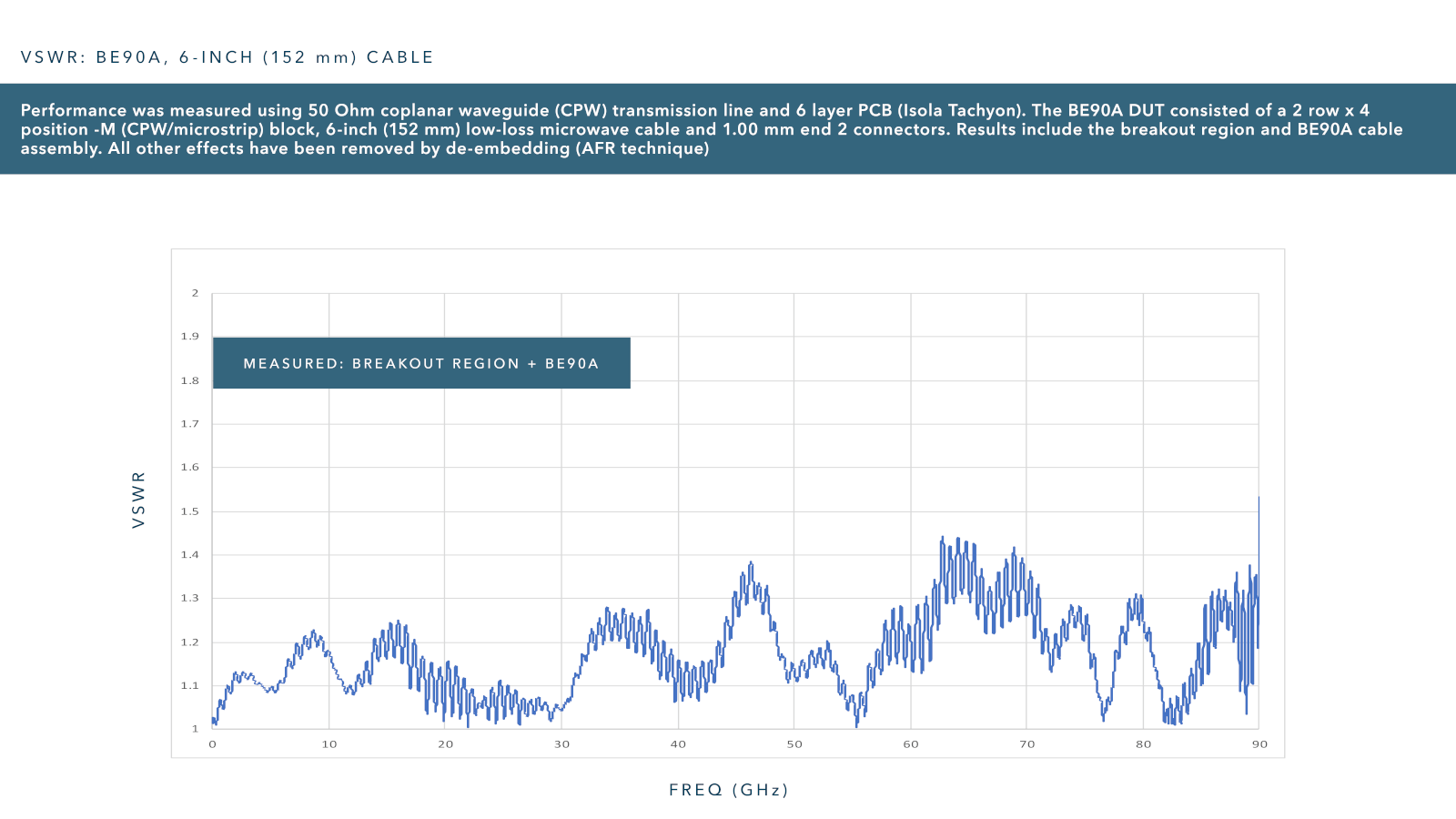

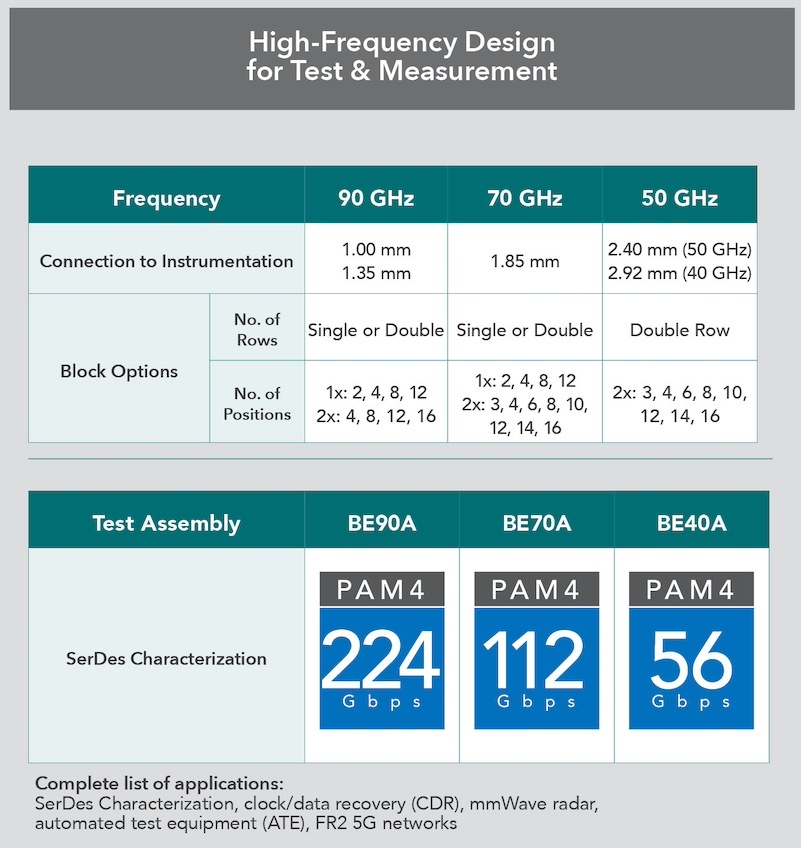

The Bulls Eye® block compression mounts to the board for placement directly adjacent to the SerDes being characterized. The solderless design improves overall cost and is easy to use within a lab setting. End 2 of the cable assembly connects to instrumentation using any of the following connector options: 1.00 mm, 1.35 mm, 1.85 mm, 2.40 mm or 2.92 mm. For near perfect fidelity for 224 Gbps PAM4 SerDes characterization BE90A is the assembly of choice. However, as proven in Samtec’s live 224 Gbps PAM4 demonstration, the BE70A assembly is also capable of handling 224 Gbps PAM4 when taking certain SI optimizations into consideration (contact [email protected]).

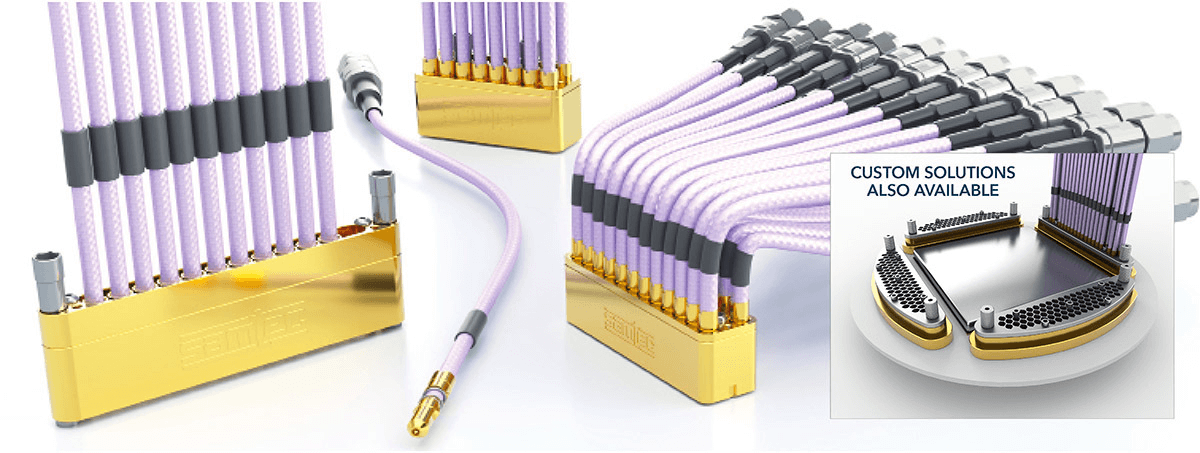

Samtec’s Bulls Eye® assembly has been a proven test and measurement solution for over a decade. During this time, the need for multi-channel high speed compression mount connectors with superior signal integrity has steadily increased. As a result, Bulls Eye® assembly has also been adopted for use in clock/data recovery (CDR) for communications, millimeter wave radar systems, automated test equipment, next generation FR2 5G networks, and a variety of custom high-density high-performance designs.

Single-row options are also now available supporting smaller board real estate in emerging high-performance, high-density applications.