Enables 64 Gbps PAM4 (32 Gbps NRZ) electrical performance on 2.00 mm column pitch

Allows designers to optimize density or minimize board layer count

Two reliable points of contact, even when subjected to angled mating

Meets Telcordia GR-1217 CORE specification

Individual signal wafers with staggered differential pair design; 24–72 pairs (board connectors) and 16–96 pairs (cable assemblies)

One-piece embossed ground structure on each signal wafer to reduce crosstalk

Lowest mating force on the market: 0.36 N max per contact

Backplane cable assemblies improve signal integrity and increase signal path length at higher data rates

Samtec's Eye Speed® ultra low skew twinax cable provides increased flexibility and routability

Stub free mating

Press-fit termination

Power and Guide Modules available

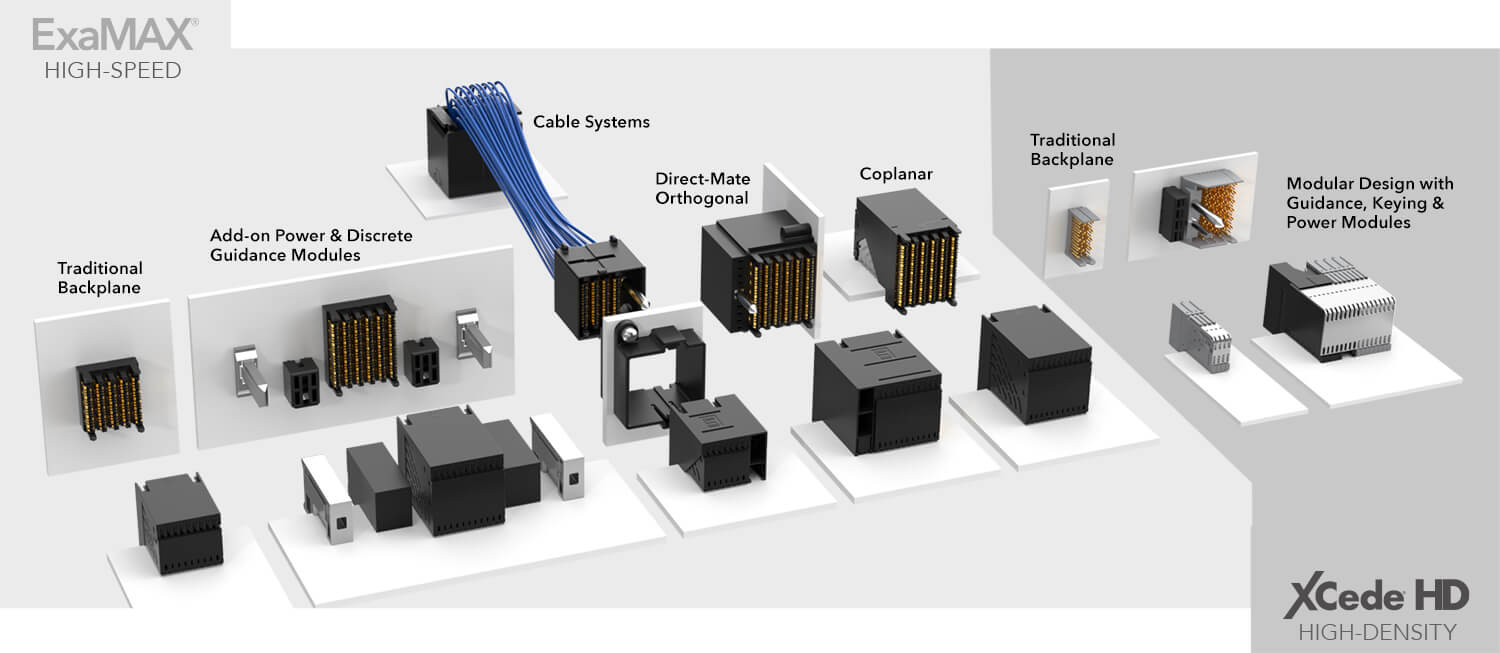

High-speed, high-density backplane systems include ExaMAX® and XCede® HD in a variety of pair and column counts. ExaMAX® enables up to 56 Gbps performance and allows designers the option to optimize density or minimize board layer count. XCede® HD is a small form factor system with a modular design for significant space savings and flexibility.

NovaRay® micro rugged backplane system enables performance to 112 Gbps PAM4 with an offset footprint and provides configurable signal banks for design flexibility.

ExaMAX® High-Speed Backplane System

ExaMAX® High-Speed Backplane SystemThe ExaMAX® backplane system offers high-density and design flexibility to fit a variety of applications, including Flyover® cable supporting 112 Gbps PAM4 and board-to-board supporting 64 Gbps PAM4 (32 Gbps NRZ).

Features

Products

XCede® HD High-Density Backplane System

XCede® HD High-Density Backplane SystemSamtec's XCede® HD high-density backplane system features a small form factor ideal for density-critical applications, and a modular design for flexibility and customizable solutions.

Features

Small form factor provides significant space savings

Modular design provides flexibility in applications

High-density backplane system – up to 84 differential pairs per linear inch

1.80 mm column pitch

3-, 4- and 6-pair designs

4, 6 or 8 columns

12–48 pairs

Up to a 3.00 mm contact wipe on signal pins

Multiple signal/ground pin staging options

Integrated power, guidance, keying and side walls available

85 Ω and 100 Ω options

Three levels of sequencing enable hot plugging

Cost-effective designs available for low-speed applications

Products

NovaRay® 112 Gbps PAM4 Micro Rugged Backplane System

NovaRay® 112 Gbps PAM4 Micro Rugged Backplane SystemNovaRay® Micro Rugged Backplane system combines ultra-high density with an offset footprint for optimal signal integrity performance to 112 Gbps PAM4.

Features

Ultra-high density with up to 128 differential pairs in a single connector

56 Gbps NRZ/112 Gbps PAM4 performance per channel

Supports blind mate applications

Surface mount for better density and performance

Offset footprint for optimum signal integrity

Flyover® cable assembly in design

Products

Standoffs, Guide Posts & Ultra Rugged Hardware

Standoffs, Guide Posts & Ultra Rugged HardwareSamtec offers a variety of SureWare™ hardware for connector support, including precision standoffs, compression alignment hardware, and guidance modules to assist with mating and help ensure a reliable connection.

Features

Standoffs for 4 mm to 30 mm stack heights

Reduces risk for component damage on boards

SureWare™ guide post standoffs (GPSO) allow for 0.035" of initial misalignment and assist with "blind mate"

Standoffs designed for PCI/104-Express™ and VITA™ standards

Guidance modules for ExaMAX® backplane systems

Products