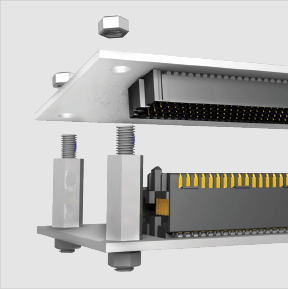

URSA® I/O features a hyperboloid-type contact for extreme reliability and high mating cycles in ultra rugged applications with EMI protection.

Rugged & High-Power Solutions

Ultra rugged systems, flexible power interconnects, and rugged contact systems combined with rugged signal integrity offerings, create the foundation of Samtec’s rugged/power solutions for high cycle, high power, high speed, and harsh environment applications. Samtec’s rugged/power products are offered in conjunction with full engineering support, online tools, and a service attitude that is unmatched in the connector industry.

Ultra

Rugged

Extreme High Mating Cycles

Rugged MIL-DTL Materials

Testing for Extreme/Harsh Applications

Flex

Power

3 to 60 Amps

Configurability of Power and Signal

Space-Saving Form Factor

Rugged

Contact System

1000+ Mating Cycles

Tiger Eye™ Heat-Treated BeCu Contacts

Multiple Points of Contact for High-Reliability

Rugged

Signal Integrity

High Speeds to 56 Gbps PAM4

Edge Rate® Contact Design Increases Wear Life

Expertise in Signal Integrity Design & Analysis

Ultra Rugged Solutions & Hardware

Ultra rugged solutions provide reliability and flexibility in small form factors, meeting or exceeding requirements for harsh environment applications – from rugged I/O systems, sealed & compact optics, and VITA 90 VNX+ modules to ultra rugged hardware and high-temp coatings.

NovaRay® I/O Panel Mount Cable System

NovaRay® I/O uses Flyover® cable technology to route up to 3,584 Gbps PAM4 aggregate data from the IC package to the panel and beyond, and is available in a rugged 38999 shell.

FireFly™ Optical Transceivers

Samtec's FireFly™ Micro Flyover System™ embedded and rugged optical transceivers take data connection "off board" for up to 28 Gbps per lane with a path to 112 Gbps PAM4 via optical cable at greater distances, or copper for cost optimization.

VITA 90 VNX+ Industry Standard Products

The VITA 90 VNX+ standard relies on the proven performance of the original VITA 74 VNX SEARAY™ connector from Samtec delivering size, weight, power and cost (SWaP-C) benefits for small form factor (SFF) applications.

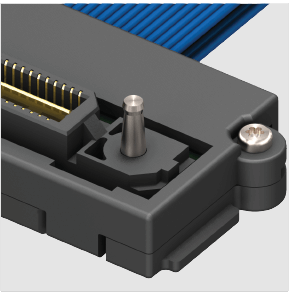

Standoffs, Guide Posts & Ultra Rugged Hardware

Samtec offers a variety of SureWare™ hardware for connector support, including precision standoffs, compression alignment hardware, and guidance modules to assist with mating and help ensure a reliable connection.

Power Systems

High power and power/signal combo connectors up to 60 Amps with high-density power blades and small form factor designs. Low profile and elevated designs, high-density power blades, individually shrouded power pins and a variety of other options available.

mPOWER® Ultra Micro Power Connectors

AcceleRate® mP 0.635 mm Signal/Power Arrays

These 0.635 mm pitch high-density, high-speed signal/power arrays achieve 64 Gbps PAM4 speeds and feature rotated power blades for improved performance and simplified breakout region (BOR).

Power Mate® and Mini Mate® Systems

High power isolated connectors; board-to-board power socket and terminal strips with individually shrouded contacts.

EXTreme Ten60Power™

Samtec's EXTreme Ten60Power™ systems feature 60 amp power connectors featuring a modular high power and signal combo for coplanar and right-angle board-to-board applications. Designed as a high-current and lower profile interconnect than existing connectors, EXTreme Ten60Power™ interconnects provide maximum current-to-length ratio packaged in a low 10 mm height housing that enhances airflow within the system.

EXTreme LPHPower™

EXTreme LPHPower™ 30 amp power connectors are extremely low profile at 7.5mm, and feature double stacked power blades for high density applications.

PowerStrip™/20 .150" Pitch High-Power Systems

PowerStrip™/20 .150" pitch high-power connectors feature up to 8 total power blades that will carry up to 20 A per blade.

PowerStrip™/30 5mm Pitch High-Power Systems

PowerStrip™/30 5mm pitch high-power connectors feature 2-10 power blades that will carry up to 30 A per blade.

PowerStrip™/40 .250" Pitch High-Power Systems

PowerStrip™/40 .250" pitch high-power connectors feature 2-8 power blades that will carry up to 40 A per blade in right-angle or vertical orientations.

Flexible Power Stacking Systems

Standard and high-temp connector strips with Power Eye contacts for applications up to 15 A per pin.

XCede® HD Power Module Connectors

Small form factor power module connectors for use as a standalone power solution or with XCede® HD connectors for micro backplane and traditional backplane applications.

ExaMAX® Power Module Connectors

Small form factor power module connectors for use as a standalone power solution or with ExaMAX® connectors for micro backplane and traditional backplane applications.

Q2™ Rugged, Shielded High-Speed Connectors

These rugged shielded high-speed connectors feature a ground plane and high-wipe contacts.

Q Rate® Slim High-Speed Connectors

Q Rate® slim high-speed connectors feature an integrated power/ground plane and rugged Edge Rate® contacts for high-reliability and performance.

Q Strip® High-Speed Ground Plane Connectors

Samtec Q Strip® high-speed ground plane connectors are designed for high-speed board-to-board applications where signal integrity is essential.

Rugged I/O Systems

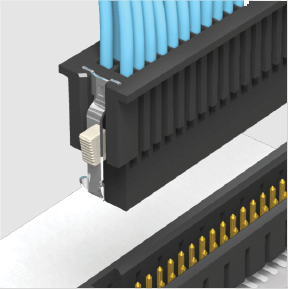

Rugged power I/O assemblies, extreme optics and sealed solutions for panel-to-board and panel-to-panel applications. Features include micro-hyperboloid contacts, EMI shielding, 38999 shells, salt fog resistance and parylene-coated, as well as IP67/IP68 sealed.

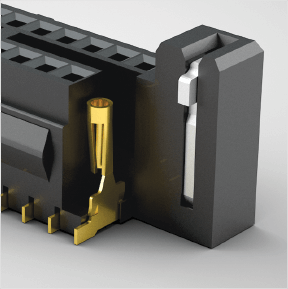

URSA® I/O

URSA® I/O features a hyperboloid-type contact for extreme reliability and high mating cycles in ultra rugged applications with EMI protection.

NovaRay® I/O Panel Mount Cable System

NovaRay® I/O uses Flyover® cable technology to route up to 3,584 Gbps PAM4 aggregate data from the IC package to the panel and beyond, and is available in a rugged 38999 shell.

FireFly™ Optical Transceivers

Samtec's FireFly™ Micro Flyover System™ embedded and rugged optical transceivers take data connection "off board" for up to 28 Gbps per lane with a path to 112 Gbps PAM4 via optical cable at greater distances, or copper for cost optimization.

AccliMate™ Mini Push-Pull

Our AccliMate™ mini push pull sealed cables are tested to IP67 for dust and water applications. They feature a lightweight plastic body and use rugged push-pull latching with visual alignment indicators.

AccliMate™ IP68 Bayonet Sealed Circular Cables

Our AccliMate™ bayonet sealed circular cables are tested to IP68 for dust and water applications.

AccliMate™ Sealed Rectangulars

Our AccliMate™ IP67 and IP68 sealed panel mount connector features a spacing saving rectangular design, tested to IP68 for dust and water.

AccliMate™ Sealed Threaded Circulars

Our AccliMate™ sealed circular cables are threaded and tested to IP68 for dust and water applications.

USB Board Level Interconnects and Cable Assemblies

Samtec’s USB board connector and cable assemblies include standard, rugged, and sealed USB Type A, USB Type B, Type AM, or Mini USB 2.0 interfaces with choice of interface type.

Rugged Board-to-Board Systems

High-reliability Tiger Eye™ contact system rated to 1,000+ mating cycles for high shock and vibration applications. Additional solutions include self-mating, ultra micro power to 18 Amps, individually shrouded power pins and one piece interfaces.

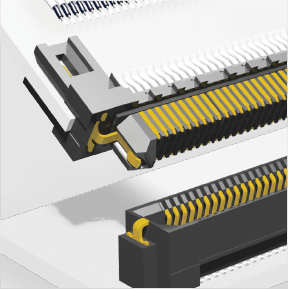

Rugged Tiger Eye™ Systems

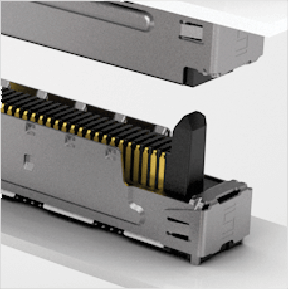

Tiger Eye™ high-cycle, high-reliability connector systems feature Samtec's most rugged contact system rated to 1,000+ mating cycles in 0.80 mm, 1.27 mm and 2.00 mm pitches, with a variety of ruggedizing options.

Power Mate® and Mini Mate® Systems

High power isolated connectors; board-to-board power socket and terminal strips with individually shrouded contacts.

mPOWER® Ultra Micro Power Connectors

Razor Beam™ Self-Mating Connectors

High-speed, high-density Razor Beam™ self mating connectors reduce inventory costs and are available in a variety of pitches and lead styles for increased flexibility.

Floating Contact Systems

Samtec's high-speed floating connectors provide 0.50 mm float in X and Y directions to minimize mating alignment errors.

Micro Pitch One-Piece

1.00 mm and .050" pitch one-piece interfaces for rugged and power applications.

.100" (2.54 mm) Pitch One-Piece

.100" pitch one piece connectors in vertical and right-angle designs with large contact deflection.

SI Lite Solutions

Samtec's SI Lite cost-effective board-stacking connectors are rated up to 8 Gbps to run high-speed signals in a variety of applications.

E.L.P.™ High Mating Cycle Connectors

These high mating cycle connectors are tested to rigorous standards which evaluate contact resistance in simulated storage and field conditions.

Rugged High-Speed Systems

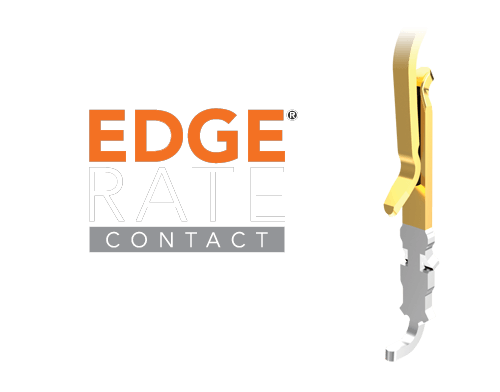

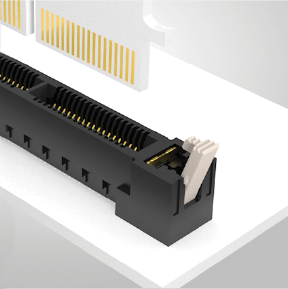

Rugged high-speed Edge Rate® contact system with an extended 1.5 mm wipe and 56 Gbps PAM4 performance. Additional solutions to 56 Gbps PAM4 performance include a variety of edge card sockets, high-density power/signal arrays, ground plane and self-mating connectors.

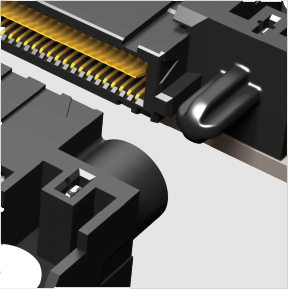

Edge Rate® Rugged, High-Speed Connector Strips

These Edge Rate® rugged high-speed connector strips feature contacts optimized for signal integrity performance, increased durability and cycle life.

High-Speed 0.60 mm Pitch Edge Card

Samtec's Generate® 0.60 mm pitch edge card sockets feature differential pair Edge Rate® contacts for 64 Gbps PAM4 (32 Gbps NRZ) performance and PCIe® 6.0 capable; compliant to SFF-TA-1002 specifications.

Generate® High-Speed 0.80 mm Pitch Edge Card Sockets

Samtec's Generate® 0.80 mm pitch edge card sockets feature Edge Rate® contacts optimized for signal integrity performance. Available in vertical, right-angle, edge mount, pass-through and power/signal combo for design flexibility.

High-Speed 1.00 mm Pitch Edge Card

Samtec's Generate® 1.00 mm pitch edge card sockets with rugged Edge Rate® contacts and misalignment mitigation support speeds up to 28 Gbps NRZ.

Micro Pitch Edge Card Sockets

These micro pitch edge card sockets come in a variety of centerlines and orientations, including 0.50 mm, 0.635 mm, 0.80 mm, 1.00 mm, 1.27 mm, and 2.00 mm, vertical, right-angle, and edge mount, as well as surface mount and through-hole tails.

AcceleRate® mP 0.635 mm Signal/Power Arrays

These 0.635 mm pitch high-density, high-speed signal/power arrays achieve 64 Gbps PAM4 speeds and feature rotated power blades for improved performance and simplified breakout region (BOR).

Q Strip® High-Speed Ground Plane Connectors

Samtec Q Strip® high-speed ground plane connectors are designed for high-speed board-to-board applications where signal integrity is essential.

Q Rate® Slim High-Speed Connectors

Q Rate® slim high-speed connectors feature an integrated power/ground plane and rugged Edge Rate® contacts for high-reliability and performance.

Q2™ Rugged, Shielded High-Speed Connectors

These rugged shielded high-speed connectors feature a ground plane and high-wipe contacts.

Razor Beam™ Self-Mating Connectors

High-speed, high-density Razor Beam™ self mating connectors reduce inventory costs and are available in a variety of pitches and lead styles for increased flexibility.

E.L.P.™ High Mating Cycle Connectors

These high mating cycle connectors are tested to rigorous standards which evaluate contact resistance in simulated storage and field conditions.

Discrete Wire Cable Assemblies

Discrete wire cable assemblies with choice of pitch from 0.80 mm to 6.35 mm and wire ranges from 32 to 10 AWG. Features include rugged latching, high-reliability Tiger Eye™ or individually shrouded contact systems, standard and high-power versions, polarization and keying. Components and tooling available for self assembly.

Tiger Eye™ .050" Pitch Discrete Wire Cables & Connectors

These Tiger Eye™ .050" pitch discrete wire cables and connectors feature high-reliability contacts for micro rugged applications.

Tiger Eye™ 0.80 mm Pitch Discrete Wire Cables & Connectors

These Tiger Eye™ micro 0.80 mm pitch discrete wire cables and connectors feature a high-reliability and high-cycle contact system.

Tiger Eye™ 2.00 mm Pitch Discrete Wire Cables & Connectors

Tiger Eye™ 2.00 mm pitch discrete wire cables and connectors designed for rugged applications.

1.00 mm Pitch Micro Mate™ Discrete Wire Cables & Connectors

Micro Mate™ 1.00 mm pitch discrete wire cables and connectors feature a space-saving design that supports cable-to-board, cable-to-cable and cable-to-panel applications.

.100" Mini Mate™ Discrete Wire Cables & Connectors

Mini Mate™ .100" pitch discrete wire cables and connectors feature individually shrouded contacts for reliability in harsh environments with up to 4.8 Amps.

Power Mate® .165" Pitch Discrete Wire Cables & Connectors

Our Power Mate® .165" pitch discrete wire cables and connectors feature individually shrouded contacts for reliability in harsh environments with up to 10.4 Amps.

mPOWER® Ultra Micro Power Discrete Wire Cables & Connectors

PowerStrip™ 5.00 mm Pitch Discrete Wire Cables & Connectors

These PowerStrip™ 5.00 mm pitch discrete wire cables and connectors are power only or combination signal/power solutions with up to 30 Amps per pin for rugged applications.

PowerStrip™ .250" Pitch High Power Discrete Wire Cables & Connectors

Samtec's PowerStrip™ .250" (6.35 mm) pitch high power discrete wire cables and connectors with up to 40 Amps per pin for rugged high power applications.

2.00 mm (.0787") Pitch Discrete Wire IDC System

Cable-to-board system for ease of termination in field applications.

Rugged Features

Options for high-reliability, high-retention and high-cycle life

Tiger Eye™ Contact System

- Smooth, flat mating area increases mating cycles and lowers contact resistance

- Heat-treated BeCu for the best combination of mechanical and electrical properties

- Surface mount, micro slot tail increases solder surface area for higher joint strength

Edge Rate® Contact System

- Smooth milled mating surface reduces wear and increases durability

- Lower insertion and withdrawal forces

- Robust when “zippered” during unmating

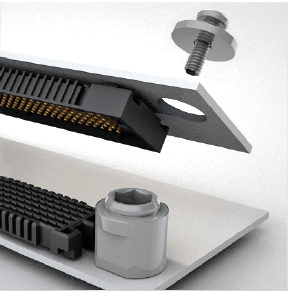

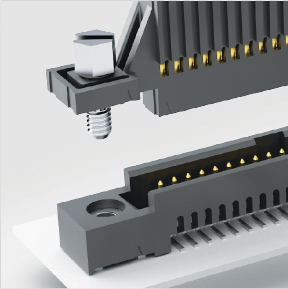

Jack Screws

Positive Latching

Friction Locks

Retention Pins

Board Locks

Weld Tabs

Guide Posts

Shielding

Screw Downs

Board Standoffs

Testing And Support

Samtec’s rugged/power products are tested to or beyond industry standards to ensure quality and performance in rugged applications.

Everything Rugged/Power

Learn More

Tools

- Solutionator®: Build a Mated Set

- Discrete Wire Solutionator®

- 3D Models

- Picture Search

-

More than 200,000 connectors and cables in our Reserve® program ship to you in 1-day. Guaranteed.

Learn more. -

For additional information or questions contact: [email protected]