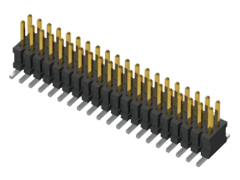

JTAG Connector Standard, JTAG Pinout Connectors

Joint Test Action Group, also known as JTAG, is the common name for IEEE standard 1149.1. This standard defines a particular method for testing board-level interconnects, which is also called Boundary Scan. In short, JTAG was created as a way to test for common problems, but lately has become a way of configuring devices. The JTAG hardware interprets information from five different signals: TDI (Test Data In), TDO (Test Data Out), TMS (Test Mode Select), TCK (Test Clock), and TRST (Test Report-optional).

The primary advantage of boundary-scan technology is the ability to observe data at the device inputs and control the data at the outputs independently of the application logic. Simple tests can find manufacturing defects such as unconnected pins, a missing device, an incorrect or rotated device on a circuit board, and even a failed or dead device.

Samtec offers both JTAG connector and cable solutions.

Standard Connectors

-

FTSH-105-01-L-DV-K – 10-pin .050” Pitch Micro Terminal Strip

-

FTSH-110-01-L-DV-K – 20-pin .050” Pitch Micro Terminal Strip

Standard Connectors with Pin 7 Removed

-

FTSH-105-01-L-DV-007-K – 10-pin .050” Pitch Micro Terminal Strip

-

FTSH-110-01-L-DV-007-K – 20-pin .050” Pitch Micro Terminal Strip

Suggested Cable Mates

-

FFSD-05-D-06.00-01-N – 6” IDC Ribbon Cable Assembly

-

FFSD-05-D-12.00-01-N – 12” IDC Ribbon Cable Assembly

Compliant Products

- EJH – .100" Shrouded IDC Ejector Header

- FTSH – .050" Micro Terminal Strip

- HHSC – .100" JTAG Ribbon Coax Cable Assembly

- HMTSW – .100" High-Temp Variable Post Height Terminal Strip

- HTSS – .100" High-Temp Shrouded Terminal Strip

- HTST – .100" High-Temp Shrouded Terminal Strip, Cable Mate

- IDSD – .100" Slim Body Double Row, IDC Ribbon Cable Assembly, Socket

- IDSS – .100" Slim Body Single Row, IDC Ribbon Cable Assembly, Socket

- MTLW – .100" Low Profile Variable Post Height Terminal Strip

- MTSW – .100" Variable Post Height Terminal Strip

- TLW – .100" Low Profile Terminal Strip

- TSM – .100" Surface Mount Terminal Strip

- TSSH – .100" End Shrouded Terminal Strip

- TST – .100" Shrouded Terminal Strip, Cable Mate

- TSW – .100" Terminal Strip

- ZSS – .100" Shrouded Elevated Terminal Strip

- ZST – .100" Shrouded Elevated Terminal Strip, Cable Mate

- ZST – .100" Shrouded Elevated Terminal Strip, Cable Mate

CONTACT SALES

First Name

Last Name

Don't want to fill out a form?

Chat with a product expert directly.

Your Privacy Choices

Your Privacy Choices