- Add to Cart

- Free Samples

- Pricing and Delivery

-

Contact our application engineering experts. We’ll connect you with a product specialist who can help you find the answers to your specific application questions.

- 1-844-558-3291

- Email a Specific Product Group

- FSE Tools

PARTS TO BE SAMPLED - UP TO 25 LINES

To get your design started even faster, we encourage you to download a 3D model here or by searching for your part number directly, then using the "Download" tab in the part viewer.

ADD TO CART

Enroll in Samtec’s

Free Sample Program

Sign up and receive FREE pieces of any

part number, anytime! We’ll even cover the shipping.

Secured form. No spam.

By signing up, you consent to the terms in our recently updated Privacy Notice and Policy Manual.

Rugged High Speed Connectors

Build your mated connector set using Samtec’s High-Speed Board-to-Board Solutionator®. Rugged high speed connectors with rugged Edge Rate® contacts, increased insertion depths, and rugged designs for contact protection during mating and unmating.

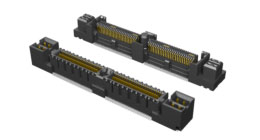

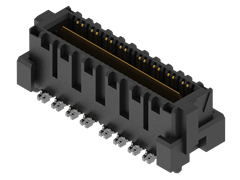

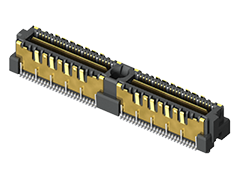

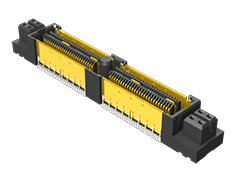

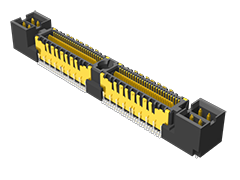

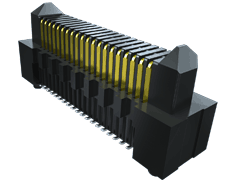

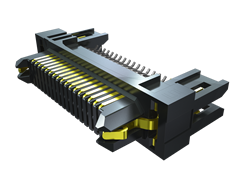

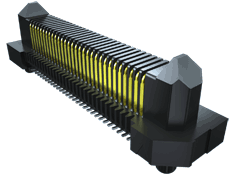

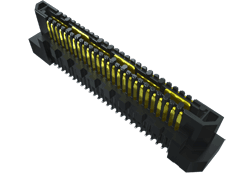

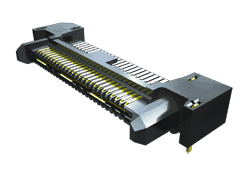

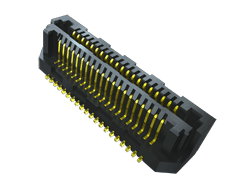

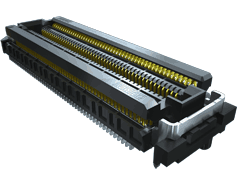

Q2™Q2™ Rugged/High-Speed Interconnects

These rugged, high-speed connectors feature a ground plane and high-wipe contacts.

Features

- Performance to 25 Gbps NRZ

- Increased insertion depth

- Dual stage hot pluggable

- Integral ground/power plane

- Shielded option available

- Power combo option

- Contacts: Up to 208 I/Os

- Stack height: 10.00 mm - 16.00 mm

Products

- QFS

- QMS

- QFS-DP

- QMS-DP

- QFS-RA

- QMS-RA

- QFS-EM

- QMS-EM

- QFS-PC

- QMS-PC

- QFSS

- QMSS

- QFSS-DP

- QMSS-DP

- QFSS-PC

- QMSS-PC

- QFSS-DP-PC

- QMSS-DP-PC

- GPSK

- GPPK

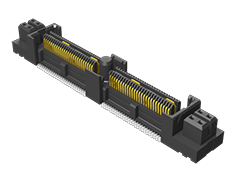

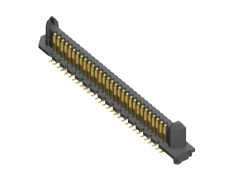

QFS

0.635 mm Q2™ High-Speed Rugged Ground Plane Socket Strip

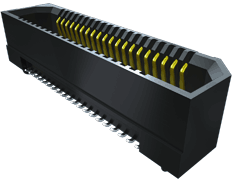

QMS

0.635 mm Q2™ High-Speed Rugged Ground Plane Terminal Strip

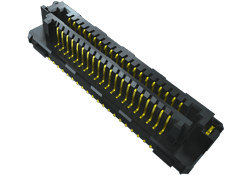

QFS-DP

0.635 mm Q2™ High-Speed Rugged Ground Plane Socket Strip, Differential Pair

QMS-DP

0.635 mm Q2™ High-Speed Rugged Ground Plane Terminal Strip, Differential Pair

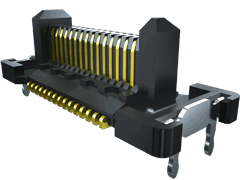

QFS-RA

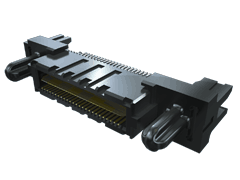

0.635 mm Q2™ High-Speed Rugged Ground Plane Socket Strip, Right-Angle

QMS-RA

0.635 mm Q2™ High-Speed Rugged Ground Plane Terminal Strip, Right-Angle

QFS-EM

0.635 mm Q2™ High-Speed Rugged Ground Plane Socket Strip, Edge Mount

QMS-EM

0.635 mm Q2™ High-Speed Rugged Ground Plane Terminal Strip, Edge Mount

QFS-PC

0.635 mm Q2™ High-Speed Rugged Ground Plane Combo Power Socket Strip

QMS-PC

0.635 mm Q2™ High-Speed Rugged Ground Plane Combo Power Terminal Strip

QFSS

0.635 mm Q2™ Shielded Ground Plane Socket Strip

QMSS

0.635 mm Q2™ Shielded Ground Plane Terminal Strip

QFSS-DP

0.635 mm Q2™ Shielded Ground Plane Socket Strip, Differential Pair

QMSS-DP

0.635 mm Q2™ Shielded Ground Plane Terminal Strip, Differential Pair

QFSS-PC

0.635 mm Q2™ Shielded Ground Plane Combo Power Socket Strip

QMSS-PC

0.635 mm Q2™ Shielded Ground Plane Combo Power Terminal Strip

QFSS-DP-PC

0.635 mm Q2™ Shielded Ground Plane Combo Power Socket Strip, Differential Pair

QMSS-DP-PC

0.635 mm Q2™ Shielded Ground Plane Combo Power Terminal Strip, Differential Pair

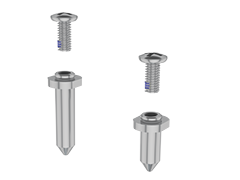

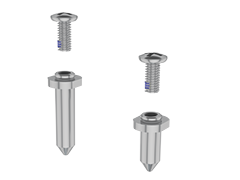

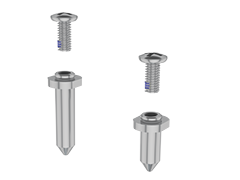

GPSK

SureWare™ Right-Angle Guide Post Socket

GPPK

SureWare™ Guide Post, Mates with GPSK

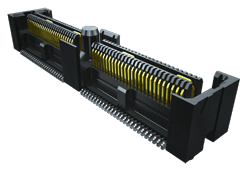

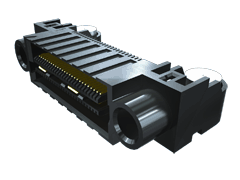

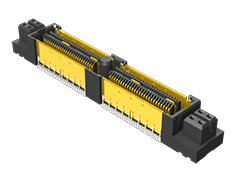

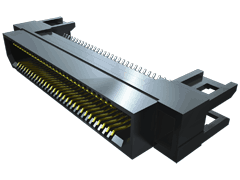

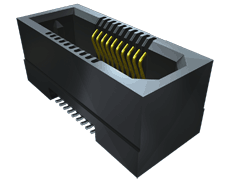

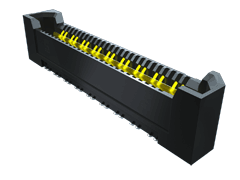

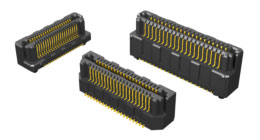

Edge Rate®Edge Rate® Connector Strips

Rugged Edge Rate® contact systems optimized for signal integrity performance.

Features

- Edge Rate® contacts optimized for signal integrity performance

- 1.5 mm contact wipe

- Robust when "zippered" during unmating

- Up to 56 Gbps PAM4 performance

- 0.50 mm, 0.635 mm or 0.80 mm pitch systems

- Stack heights from 5 mm to 18 mm

- Extremely slim 2.5 mm body width on 0.635 mm pitch system

- 0.50 mm pitch system for up to 40% PCB space savings vs 0.80 mm pitch system

Products

- ERM8

- ERF8

- ERM8-RA

- ERF8-RA

- ERM8-EM

- ERF8-EM

- ERM8-S

- ERF8-S

- ERM5

- ERF5

- ERF5-RA

- ERF6

- ERM6

- GPSK

- GPPK

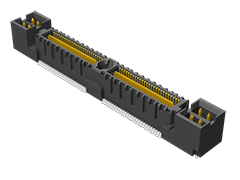

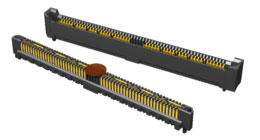

ERM8

0.80 mm Edge Rate® Rugged High Speed Terminal

ERF8

0.80 mm Edge Rate® Rugged High Speed Socket

ERM8-RA

0.80 mm Edge Rate® Rugged High Speed Terminal, Right-Angle

ERF8-RA

0.80 mm Edge Rate® Rugged High Speed Socket, Right-Angle

ERM8-EM

0.80 mm Edge Rate® Rugged High Speed Terminal, Edge Mount

ERF8-EM

0.80 mm Edge Rate® Rugged High Speed Socket, Edge Mount

ERM8-S

0.80 mm Edge Rate® Rugged High Speed Terminal, Shielded

ERF8-S

0.80 mm Edge Rate® Rugged High Speed Socket, Shielded

ERM5

0.50 mm Edge Rate® Rugged High Speed Terminal

ERF5

0.50 mm Edge Rate® Rugged High Speed Socket

ERF5-RA

0.50 mm Edge Rate® Rugged High Speed Terminal, Right-Angle

ERF6

0.635 mm Edge Rate® Rugged High Speed Socket

ERM6

0.635 mm Edge Rate® Rugged High Speed Terminal

GPSK

SureWare™ Right-Angle Guide Post Socket

GPPK

SureWare™ Guide Post, Mates with GPSK

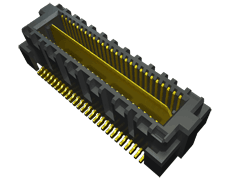

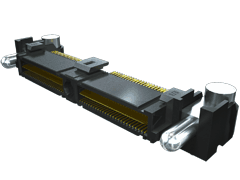

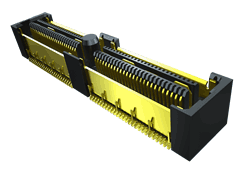

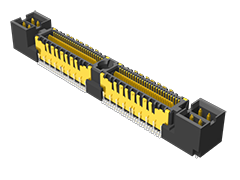

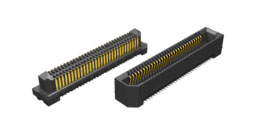

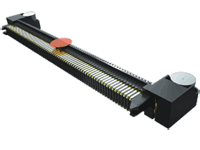

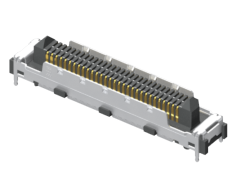

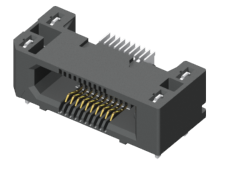

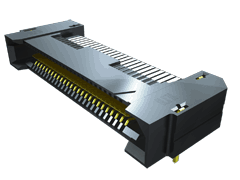

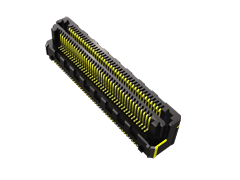

Q Rate®Q Rate® Slim, Rugged High-Speed Interconnects

Samtec Q Rate® connectors have a slim footprint, integral power/ground plane, and Edge Rate® contacts for superior SI performance.

Features

- Performance to 28 Gbps

- Rugged Edge Rate® contacts

- Integral ground/power plane

- Up to 156 positions

- Slim footprint (less than 5.00 mm wide)

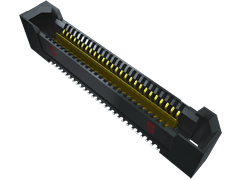

QRF8

0.80 mm Q Rate® Slim Body Ground Plane Socket

QRM8

0.80 mm Q Rate® Slim Body Ground Plane Header

QRF8-DP

0.80 mm Q Rate® High-Speed Ground Plane Slim Body Socket Strip, Differential Pair

QRF8-RA

0.80 mm Q Rate® High-Speed Ground Plane Slim Body Socket Strip, Right-Angle

QRM8-DP

0.80 mm Q Rate® High-Speed Ground Plane Slim Body Terminal Strip, Differential Pair

QRM8-RA

0.80 mm Q Rate® High-Speed Ground Plane Slim Body Terminal Strip, Right-Angle

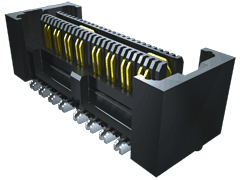

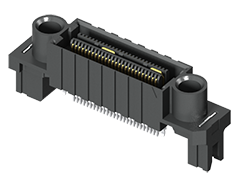

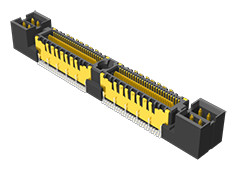

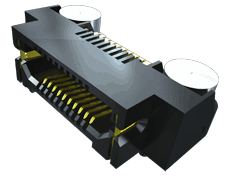

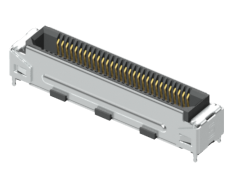

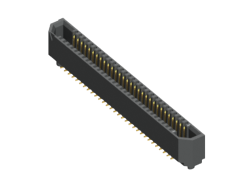

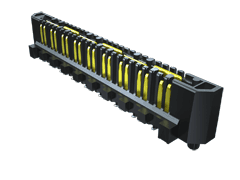

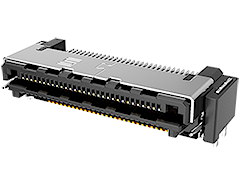

Razor Beam™Razor Beam™

High-speed, high-density Razor Beam™ self-mating systems reduce inventory costs and are available in a variety of pitches and lead styles for increased flexibility.

Features

- 0.50 mm, 0.635 mm or 0.80 mm pitch systems

- Razor Beam™ contacts for high-speed and fine-pitch systems

- Mating and unmating forces approximately 4-6x greater than typical micro pitch connectors

- Shielded option for EMI protection

- Self-mating connectors reduce inventory costs and can be interchanged for varying stack heights

- 10 stack height options from 5 mm to 12 mm

- Up to 100 contacts

- Parallel, perpendicular and coplanar systems

- Audible click when mated

- Lubricated option available

LSHM

0.50 mm Razor Beam™ High-Speed Hermaphroditic Terminal/Socket Strip, Optional Shielding

LSHM-S

0.50 mm Razor Beam™ Shielded High-Speed Hermaphroditic Strip

LSS

0.635 mm Razor Beam™ High-Speed Hermaphroditic Terminal/Socket Strip

LSEM

0.80 mm Razor Beam™ High-Speed Hermaphroditic Terminal/Socket Strip

JSO

SureWare™ Jack Screw Precision Board Stacking Standoff

GPSK

SureWare™ Right-Angle Guide Post Socket

GPPK

SureWare™ Guide Post, Mates with GPSK

Floating Contact SystemHigh Speed Floating Connectors

These high speed floating connectors provide 0.50 mm of float in the X and Y directions to minimize mating alignment errors.

Features

- Provides 0.50 mm (.0197") float in X and Y directions

- Ideal for multiple connectors on a board

- Up to 60 floating contacts

- Choice of body height and right-angle design

Products

- FT5

- FS5

FT5

0.50 mm High-Speed Floating Contact Terminal Strip

FS5

0.50 mm High-Speed Floating Contact Socket Strip

© 2024 Samtec. All rights reserved.

SPEAK WITH A REPRESENTATIVE

1-800-726-8329

1-800-SAMTEC-9

1-812-944-6733

Your Privacy Choices

Your Privacy Choices