| Product Types |

|---|

|

|

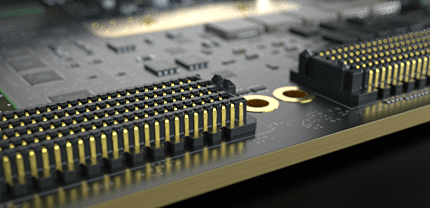

Samtec offers the largest variety of board-to-board connectors in the industry. Popular applications include high speed mezzanine and high density array systems, high speed edge card and backplane systems, and micro pitch board stacking systems down to 0.40 mm pitch and 1 mm stack height. Micro rugged products feature Samtec's Tiger Eye™ contact system on a variety of pitches, as well as high power strips and signal/power combination connectors to 60A/blade. Standard board-to-board header and socket systems are available in a variety of pitch, density, stack height, and orientation. Build your mated connector set using Samtec’s High-Speed Board-to-Board Solutionator®.

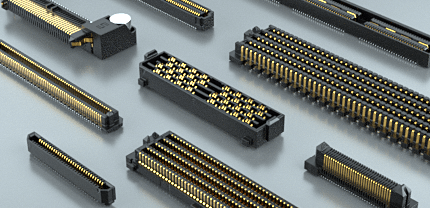

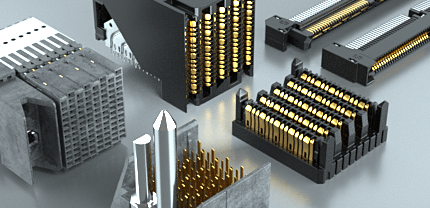

High-Speed Board-to-Board Connectors

|

|---|

|

High speed connectors, mezzanine systems with integral ground planes, high-density arrays, backplane interconnects, rugged signal integrity optimized Edge Rate® systems and high-speed performance to 56 Gbps NRZ/112 Gbps PAM4. |

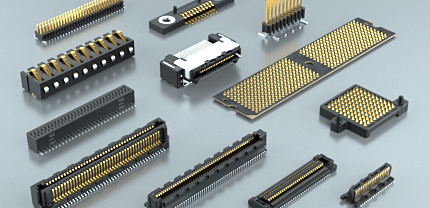

Micro Pitch Board-To-Board

|

|---|

|

Fine pitch board-to-board connectors with availability as small as 0.40 mm and stack heights as low as 1 mm. |

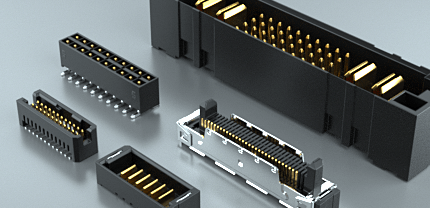

Rugged / Power

|

|---|

|

Rugged high power connectors designed to meet high current applications, and micro rugged interconnects for high-reliability, high-retention and high cycle life. |

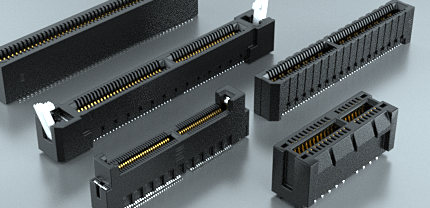

Edge Card Connector Systems

|

|---|

|

High-speed card edge connectors and systems on choice of 0.50 mm, 0.60 mm, 0.635 mm, 0.80 mm, 1.00 mm, 1.27 mm or 2.00 mm pitch and a variety of orientations. |

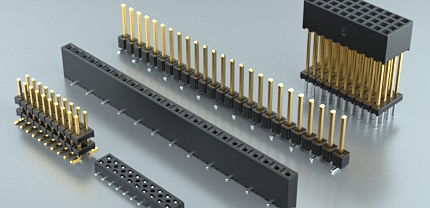

Standard Board-To-Board Terminal Strips

|

|---|

|

Board stacking terminal strips and connectors for low profile, elevated, pass-through, and rugged applications on .100" (2.54 mm) and 2.00 mm pitch. |

Backplane Connectors / Micro Backplane

|

|---|

|

These Backplane Connectors and systems such as the ExaMAX® high-speed backplane system offer 56 Gbps PAM4 performance. XCede® HD high-density backplane solutions offer design flexibility and micro backplane solutions including edge card sockets, high-density arrays, integral ground planes and rugged Edge Rate® interconnects. |

Industry Standards

|

|---|

|

Certified or compliant to most industry standards, including VITA, PCIe®, PC/104™, QSFP+, InfiniBand™, JTAG, etc. |

Your Privacy Choices

Your Privacy Choices