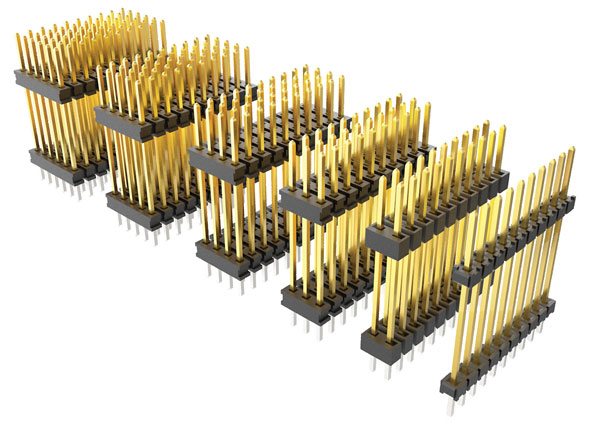

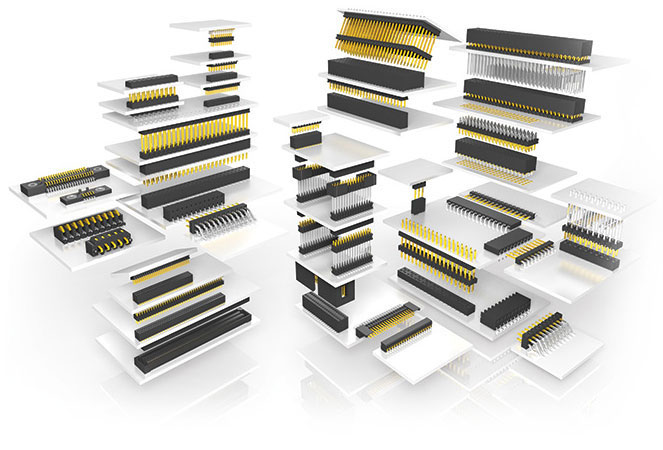

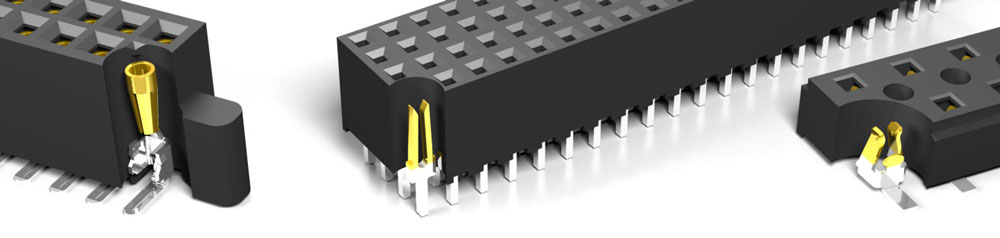

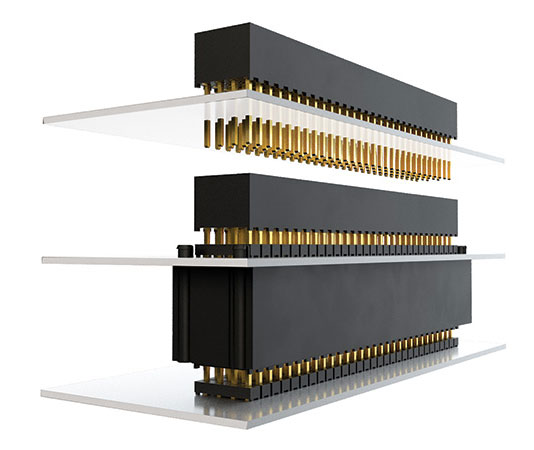

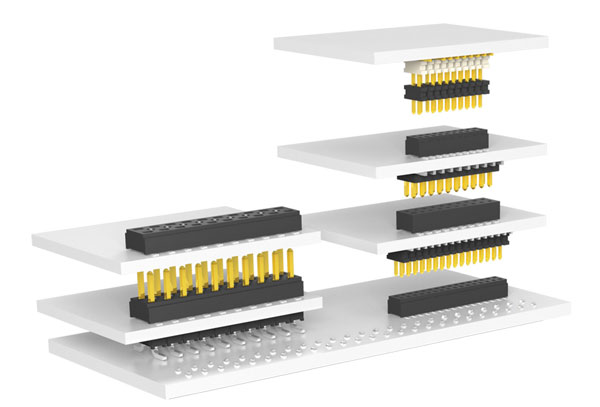

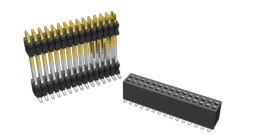

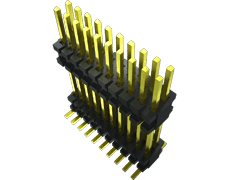

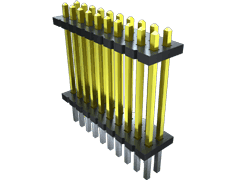

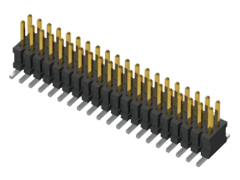

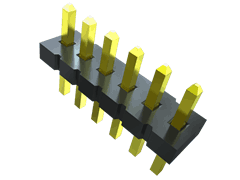

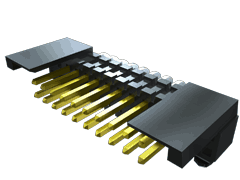

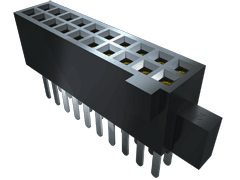

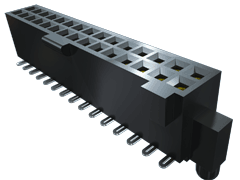

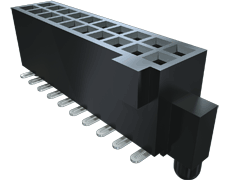

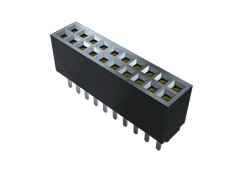

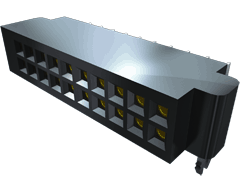

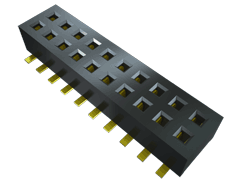

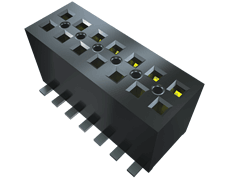

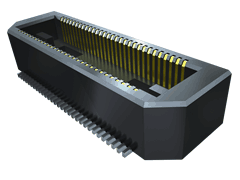

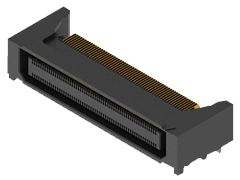

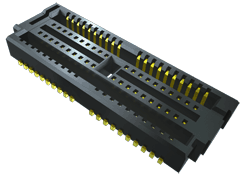

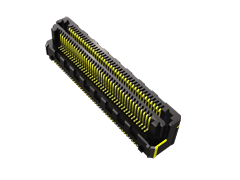

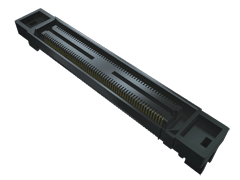

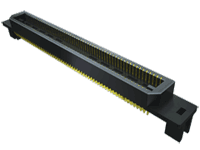

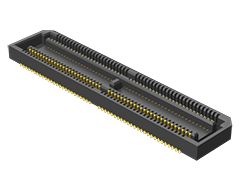

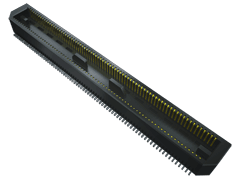

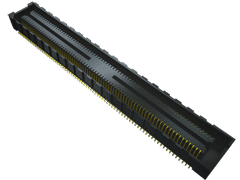

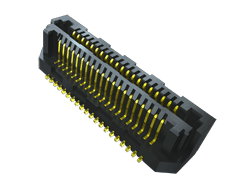

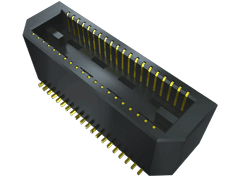

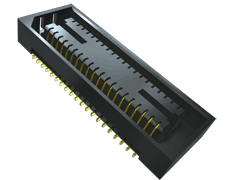

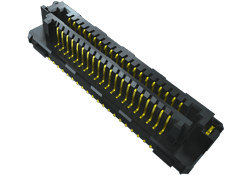

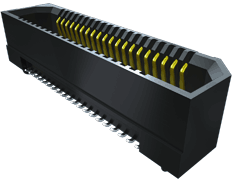

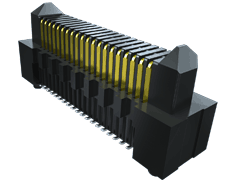

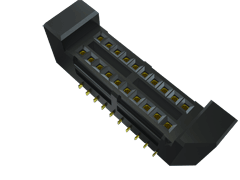

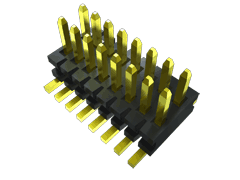

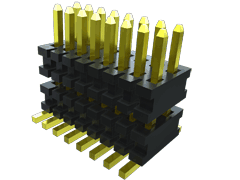

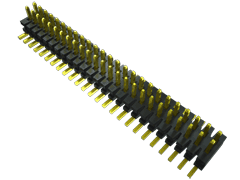

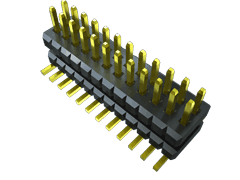

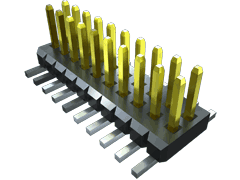

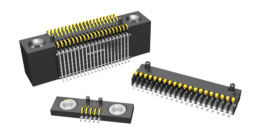

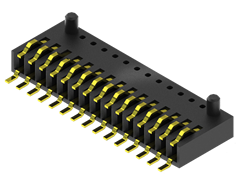

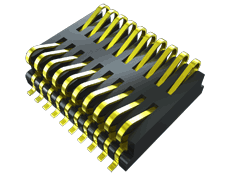

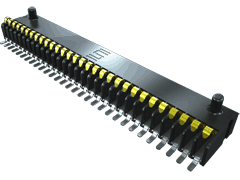

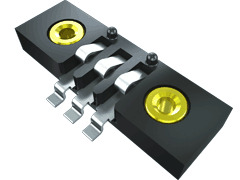

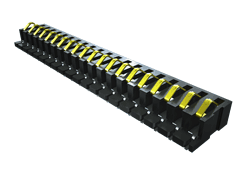

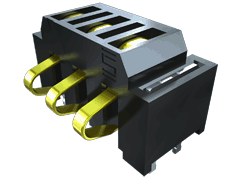

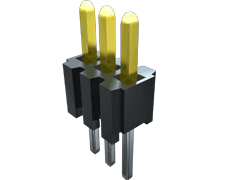

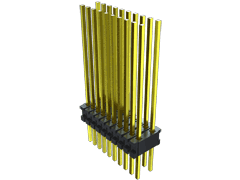

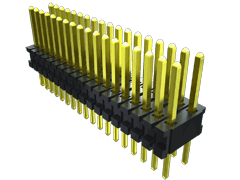

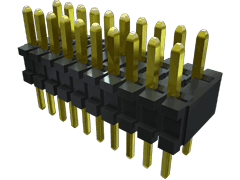

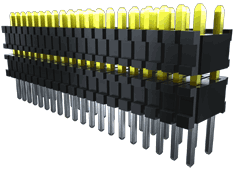

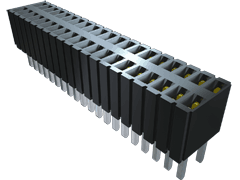

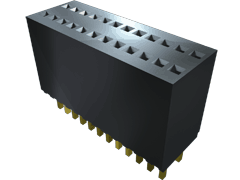

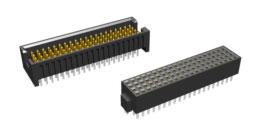

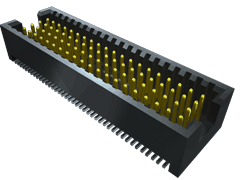

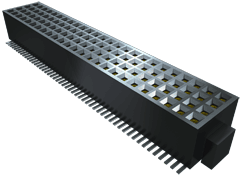

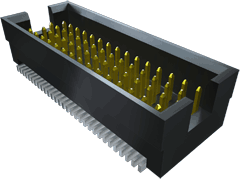

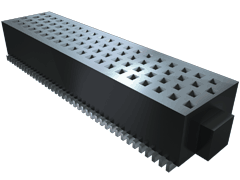

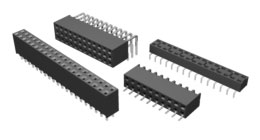

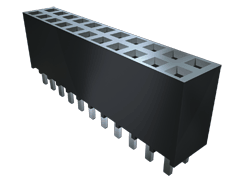

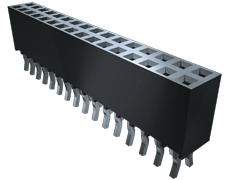

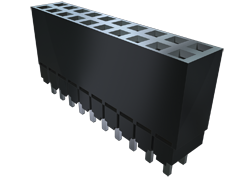

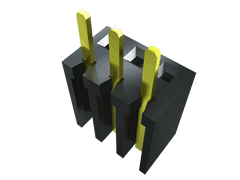

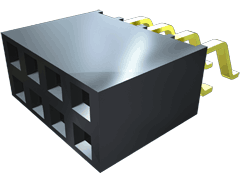

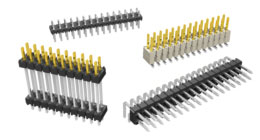

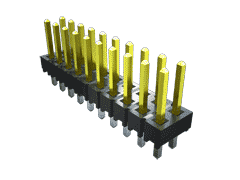

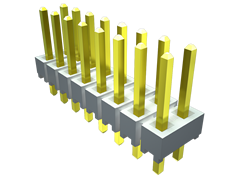

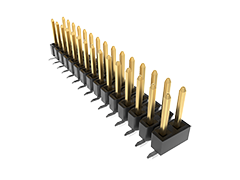

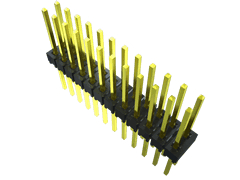

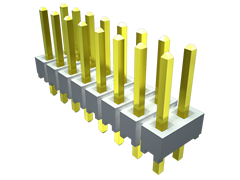

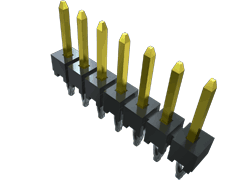

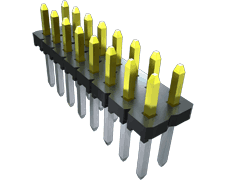

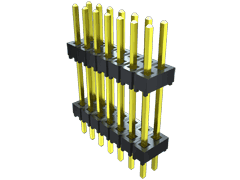

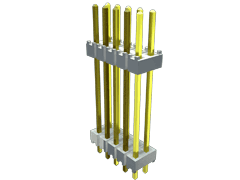

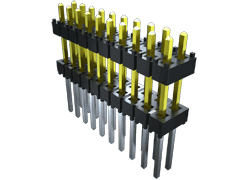

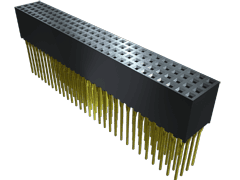

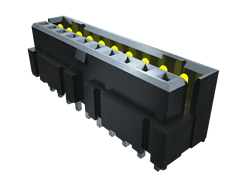

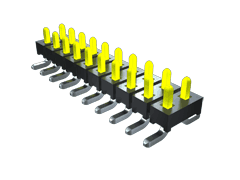

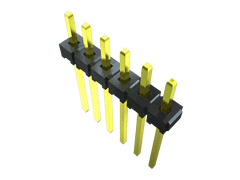

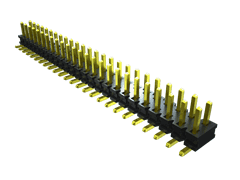

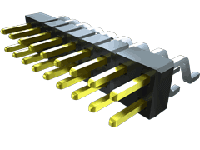

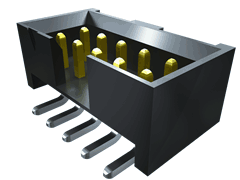

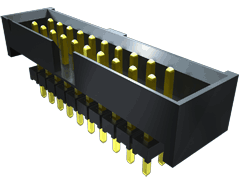

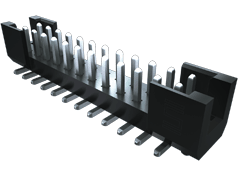

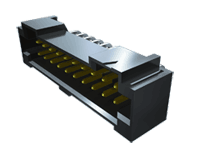

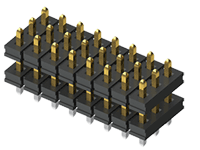

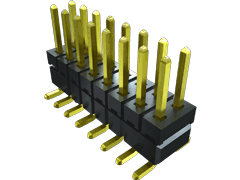

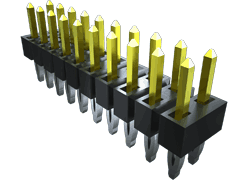

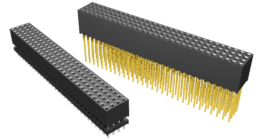

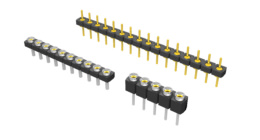

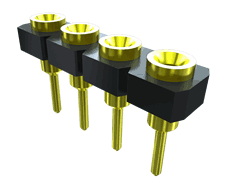

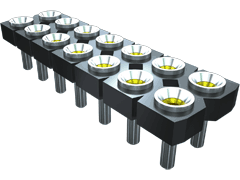

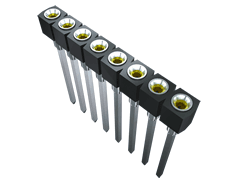

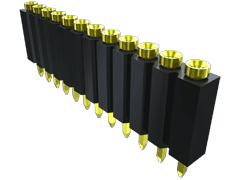

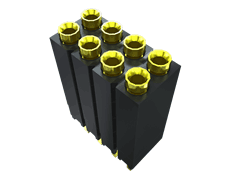

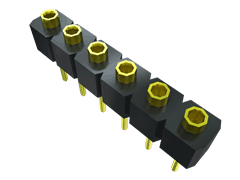

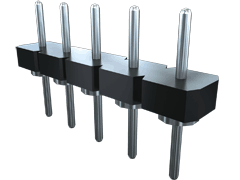

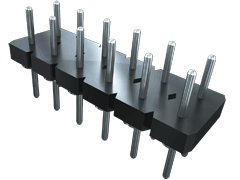

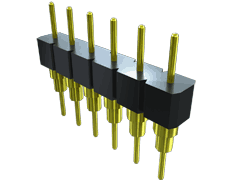

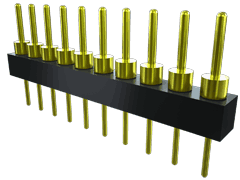

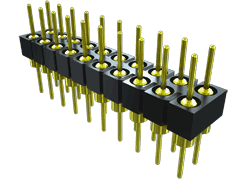

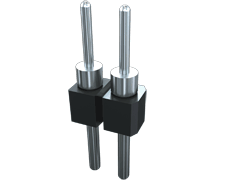

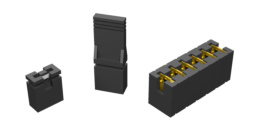

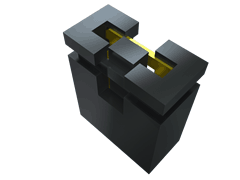

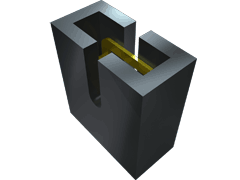

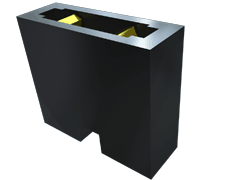

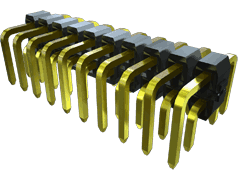

Flexibility: Modified Stackers

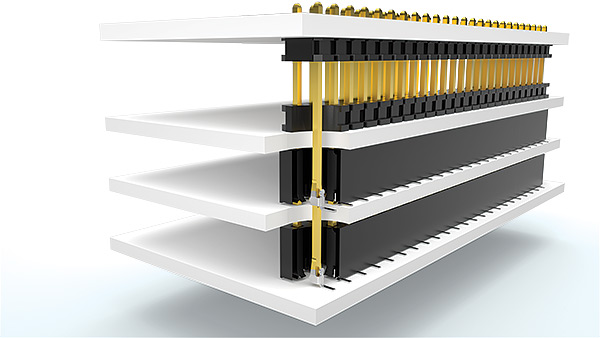

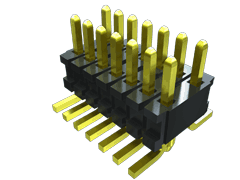

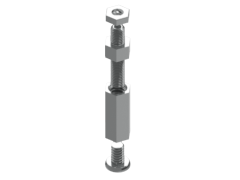

- Ability to move the body on the pin in .005" (0.13 mm) increments

-

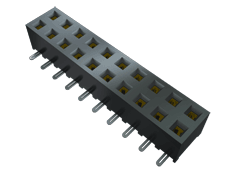

Designer receives a "custom" interconnect system that meets design specifications

- Custom stack height or post height

- Standard part number

- No minimum order requirement

- No tooling charge

- No custom lead times

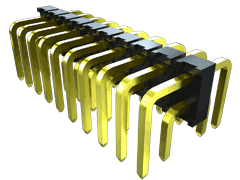

- Variety of pitches: 5.08 mm, .100" (2.54 mm), 2.00 mm, 1.00 mm, 0.80 mm

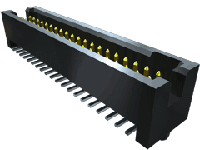

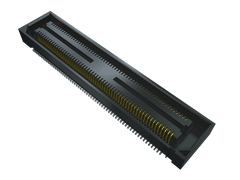

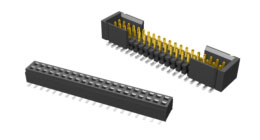

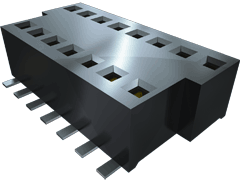

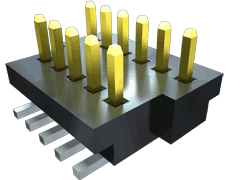

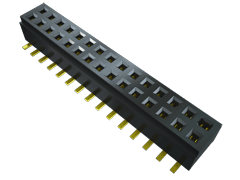

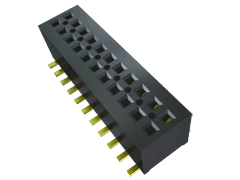

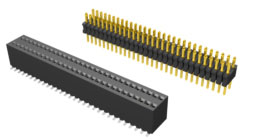

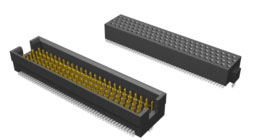

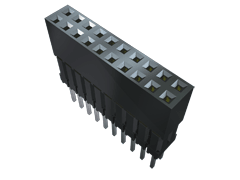

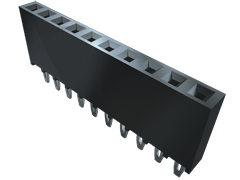

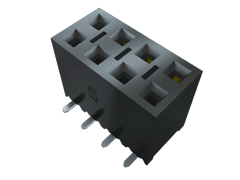

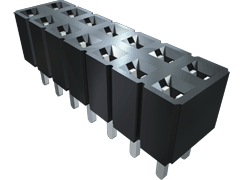

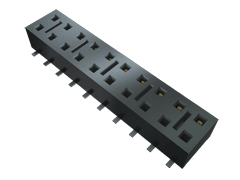

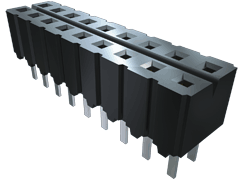

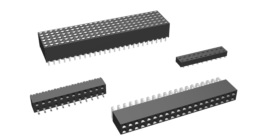

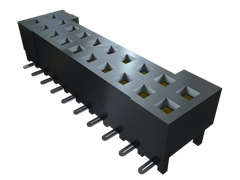

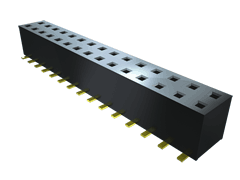

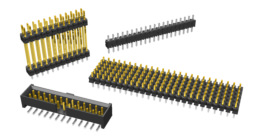

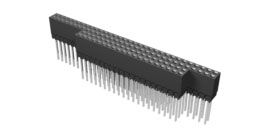

| CENTERLINE | PRODUCT | STACKER / HEADER | THROUGH-HOLE / SMT | POPULAR MATING SOCKETS* |

|---|---|---|---|---|

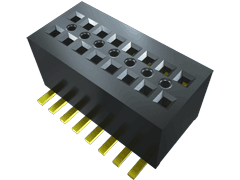

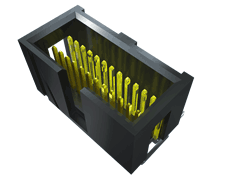

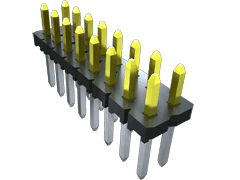

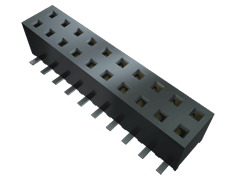

| 2.54 mm (.100") | DW | Stacker | Through-Hole | SSW, SSQ, SSM, BCS, HLE |

| 2.54 mm (.100") | EW | Stacker | Through-Hole | SSW, SSQ, SSM, BCS, HLE |

| 2.54 mm (.100") | ZW | Stacker | Through-Hole | SSW, SSQ, SSM, BCS, HLE |

| 2.54 mm (.100") | HW | Stacker | Through-Hole / SMT | SSW, SSQ, SSM, BCS, HLE |

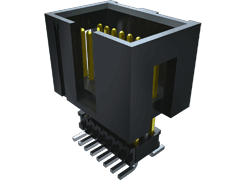

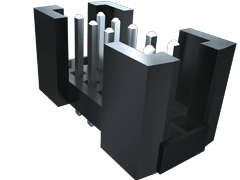

| 2.54 mm (.100") | HMTSW | Flexible Header | Through-Hole | SSW, SSQ, SSM, BCS, HLE |

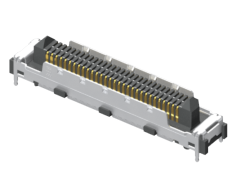

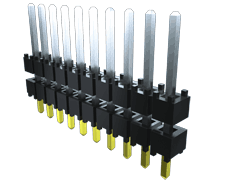

| 2.00 mm (.0787") | TW | Stacker | Through-Hole | SQW, SQT, TLE, SMM, MMS |

| 2.00 mm (.0787") | MTMM | Flexible Header | Through-Hole | SQW, SQT, TLE, SMM, MMS |

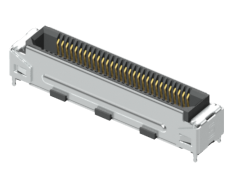

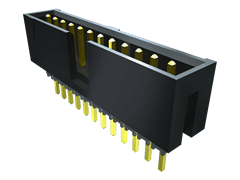

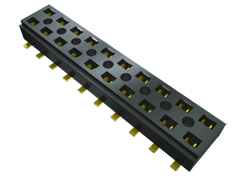

| 1.27 mm (.050") | FW | Stacker | SMT | CLP, FLE |

| 1.27 mm X 2.54" (.050" X .100") | HDWM | Stacker | Through-Hole / SMT | RSM, SMS |

| 1.27 mm X 2.54" (.050" X .100") | HMTMS | Flexible Header | Through-Hole | RSM, SMS |

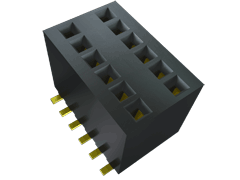

| 1.00 mm | MW | Stacker | SMT | CLM, MLE |

| 0.80 mm | AW | Stacker | SMT | CLE |

* This is not a complete list of mating socket strips

Your Privacy Choices

Your Privacy Choices